| |

|

Infomercial from

Mitsuba Systems

| |

|

|

| |

|

|

| |

Mitsuba - Multistatic 700 Series

Corona Powder Spray System |

|

| |

Mitsuba Systems - India an ISO 9001:2000

company is a leading manufacturer of powder coating

equipments. |

|

| |

Mitsuba - Multistatic 700 Corona Powder Spray System : |

|

| |

The Mitsuba Multistatic Powder Spray System has received US

Patent for their innovative technology. The gun has a patented

replaceable power cartridge (Mitsuba US Patent no. 5678770).

|

| |

|

|

| |

To know more about Mitsuba Products please Visit

www.powdergun.com

OR

Contact Us:

MITSUBA SYSTEMS (INDIA) PVT

LTD,

34/H, Laxmi Industrial Estate,

New Link Road,

Andheri (W),

Mumbai– 400 053.

TEL: 0091-22-2631 8633/2633 4735/56924151/52/53/54

FAX: 0091-22-56924154.

Email :

mitsuba@vsnl.com

|

|

| |

|

|

|

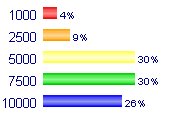

Powder Application Equipment operating in India

IPC exclusive

In continuation of our survey of Indian Powder Coating Industry, we

have further tried to estimate the total number of powder application equipment in this country. In our last newsletter we had

introduced an opinion poll which invited a feedback on the this

figure.

The voting results are indicated in the picture

Let us do some calculations...

We assume an average of 15 kg of powder being sprayed by a single

application equipment in one eight hour working day and 300 working

days an year. To spray 18,000 tons (The estimated figure of powder

produced during the last year) India would need

18,000*1000/(300*15)

=

4000 application equipment to spray this powder.

The powder production rose by about 5000 tons during the past year

adding a market for 1100 equipment.

Moderator: We thank all

those who helped to compile these details. We will continue to conduct

similar surveys and share the results with you. Your suggestions and

support are most welcome. While we have used our best efforts in

collecting and preparing the information we do not assume, any

liability for any loss or damage caused by errors or omissions,

whether such errors or omissions resulted from negligence, accident or

other causes. The subscribers may use their own discretion while using

the information.

If you need to launch any specific opinion poll, please contact the

moderator

Major Indian paint company interested in Tambour shares

Asian Paints, India’s largest paint company, has submitted a

preliminary bid for the opening of negotiations to acquire up to half

of Israel paint company Tambour. Tambour parent company Granite

Hacarmel Investments notified the Tel Aviv Stock Exchange that it had

received a number of inquiries from companies interested in buying

Tambour shares. Granite Hacarmel said that no negotiations had

resulted yet from these contacts. A source close to Tambour said that

talks between the Tambour and Asian Paints were still preliminary, and

that no negotiations had begun yet.

Nordson Corporation Co-founder Evan W. Nord Passes Away

WESTLAKE, Ohio, June 22

Evan W. Nord, 84, a philanthropist who co-founded what became Nordson

Corp., which has its world headquarters in Westlake, died Monday in

Columbia, S.C.

Nord pioneered the design and manufacture of the tungsten carbide

flat-spray nozzle for spraying pigmented coating materials, one of the

keystones of the Nordson industrial equipment empire.

In 1954 he teamed with his father, Walter, and brother Eric T. to

start Nordson as a division of U.S. Automatic Co. in Amherst to

manufacture airless spray equipment. A dozen years later the division

absorbed its parent company.

Today, Nordson has 3,500 employees worldwide and 652 in Northeast

Ohio. It sells industrial spray application systems for paints,

coatings, adhesives and sealants throughout the world.

Nord moved to Blythewood, S.C., after retiring from daily operations

at the Amherst plant in 1978.

In March 2002, when Nord retired from the Nordson board of directors,

Worth magazine named him the wealthiest person in Columbia. The value

of his Nordson stock was estimated at $116 million.

Nord served as president of the Nordson Foundation. He and his wife,

Cynthia, were committed to helping their communities and the

disadvantaged.

They established the Evan and Cindy Nord Fund with the Lorain County

Community Foundation.

Nearly $600,000 from the fund was awarded to Common Ground, also known

as the Cindy Nord Center for Renewal, a Vermilion-area retreat started

by the Humility of Mary religious order.

Nord, a member of many social-service boards, helped launch the

Oberlin Early Childhood Center, the Oberlin Community Center and the

W.G. Nord Mental Health Center. He led the restoration of historic

buildings and homes.

The Amherst native graduated from Amherst High School in 1937.

He was inducted into the Amherst Schools Distinguished Alumni Gallery

of Success in 1992. He received a bachelor's degree in mechanical

engineering from the Case School of Applied Science in 1941.

He was a teenager when he started working for U.S. Automatic Corp.,

which was owned by his father. He joined the Navy in 1944 and served

in both the At lantic and the Pacific during World War II. After the

war, he returned to the family business and became vice president of

manufacturing before starting Nordson.

He continued his community service as a volunteer and benefactor in

South Carolina. He served on the boards of the Carolina Children's

Home, South Carolina State Museum and Heathwood Hall Foundation. He

was a charter member of the Central Carolina Community Foundation and

donated $40 million to the organization.

"We're doing it to set an example," Nord said in a 1992 interview.

"We're using our children's inheritance and we're using our

inheritance and the money we've worked for and sweated for to try to

make a difference."

Nord and his wife lived a quiet life on their 150-acre horse farm just

north of Columbia. In 1995, they were named Humanitarians of the Year

by the United Way of the Midlands.

He is survived by his wife; sons, Eric, Bruce and Ethan; daughters,

Katie

Peterson and Allyson Wandtke; his brother, of Oberlin; and nine

grandchildren.

Reality TV Discovers Paint

Coatings Magazine E-news - June 3, 2004

Finally it's happened. Reality TV has hit the paint industry. If you

can create a reality TV show about married couples exchanging partners

or transforming plain, insecure women into beauty queens, why not make

something about paint?

Paint has finally made it onto the public radar. In the first case,

paint from Pittsburgh Paint was highlighted in an Extreme

Makeover-Home Edition show. The company's paints were used to paint

the apartment of two New York City firemen. The company donated 35

gallons of its Manor Hall line of paints and primers for the project.

It's not such exciting news in and of itself, but it did highlight the

fact that paint is an important part of home renovations and that is

simply good PR for consumer paints.

The second recent news item is a bit strange, but again puts paint on

the public radar. The latest reality TV concept is about watching

paint dry. Really. Billed as the "ultimate reality TV show," a British

pay-channel has developed a live, eight-week round-the-clock webcast

that will literally feature watching paint dry.

It is, of course, a tongue-in-cheek program that is making a comment

on the dullness of the endless and hugely popular reality TV shows

that seem to be on every channel, but hey, it's still featuring paint

and it's in the news. Again, it's great PR. People that go to the

webcast will be able to vote for their favourite paint finish; gloss,

satin or matt, with the least favourite being voted out each week

before revealing the British nation's choice.

So, finally, when people say that something is as dull and boring as

watching paint dry, we in the industry may beg to differ…or at least

ask these people if they have a reality TV show based on their

product.

Akzo Nobel Car Refinishes introduces unique peelable paint

Arnhem, the Netherlands, June 11, 2004 - Akzo Nobel has developed a

unique temporary paint system which can be peeled off after use. Known

as Maskin®, the product can be applied to any non-porous surface -

such

as a vehicle body or windows - without risk of damage to the original

finish.

Astral Industries cut its toxic chemical releases

Steel burial-casket maker Astral Industries in the Randolph County

community of Lynn cut its toxic chemical releases from 195,799 pounds

in 2001 to 137,990 pounds in 2002. Micah Stuckey, facilities

engineering assistant, attributed the decrease to switching from

lacquer painting to powder coating in painting the caskets.

The Allegheny Ludlum stainless steel factory here continues to be the

largest emitter of toxic chemicals in East Central Indiana, according

to the U.S. Environmental Protection Agency's latest annual Toxic

Release Inventory.

<more>

Cloverdale Paint and Rodda Paint to merge

*Coatings Flash - June 07, 2004

Cloverdale Paint Inc. and Rodda Paint Co., two well-respected family

owned regional paint companies in the USA, have reached an agreement

in principle to merge the two companies. Cloverdale Paint Inc. employs

650, operates 65 branches in Western Canada and Washington State, and

has four manufacturing plants in Canada. Rodda Paint Co. employs 350,

operates 41 branches in Washington, Oregon, Northern Idaho and Alaska

and a manufacturing plant in Portland, Oregon. The merged operation

will continue to operate under the Cloverdale name in Canada and under

the Rodda name in the United States. It is intended that each

operation will be managed independently by existing personnel.

SigmaKalon acquired Primalex

Coatings Flash

- June 07, 2004

SigmaKalon has acquired Primalex from The Riverside Company, a private

equity fund based in Europe and North America. With sales of 20

million euros, Primalex is the market leader for wall paints in the

Czech Republic and Slovakia. The Primalex brand name is the leading

brand on the Czech and Slovak decorative paint markets. The company

has production facilities in Brasy (Czech Republic) and Dolný Kubín

(Slovakia) and employs 135 people in production, R&D, sales and

marketing.

"We are very pleased to announce this new expansion of our business

into the Czech Republic and Slovakia at a time when these countries

look set to enjoy the benefits of their newly acquired EU membership",

said SigmaKalon CEO, Pierre-Marie De Leener. "Primalex is a good fit

with our operations in neighbouring countries Poland and Hungary and

we see a number of interesting synergies within our Central European

activities". The Czech and Slovakian decorative paint markets are

evaluated at 120,000 tons of which a vast majority are wall paints.

Classic Reference Manual for Paint and Coatings Industry Updated for

first time in 18 years

Norwich, NY - William Andrew Publishing announces the acquisition of

North/South American rights for the just updated Handbook on Basics

of Coating Technology. This is an indispensable reference for anyone

in the industry. Whether they are involved in traditional processes

or the most innovative, this handbook is a critical addition to daily

routines.... <more>

PPG Total Service Solutions Wins Its First Chemical and Process

Management Contract in China

TROY, Mich., June 8 -- PPG Total Service Solutions recently signed a

contract with Wuxi Vehicle Body Co. to provide the vehicle

manufacturer

with a chemical and process management program at its facility in Wuxi,

China....

Industries Honored by the

Sanitation Districts of Los Angeles County for Being ``Good Corporate

Citizens''

WHITTIER, Calif.--(BUSINESS WIRE)--June 23, 2004--Nearly 400 companies

were presented with Year 2003 Certificates of Recognition by the

Sanitation Districts of Los Angeles County for being "good corporate

citizens." These companies were in consistent compliance with all

their industrial wastewater discharge requirements for 2003. They met

their limits for wastewater discharge; they were free from any notices

of violation; they maintained their environmental equipment; and they

fulfilled their permit requirements. Over 80 of the companies received

this recognition for each of the last four years.

"As far as we're concerned, the 381 industries receiving certificates

are our model citizens," notes James Stahl, Chief Engineer and General

Manager of the Sanitation Districts. "We appreciate their effort

because it makes our job of running a huge wastewater collection and

treatment system so much easier."

Paul Martyn, head of the Sanitation Districts' Industrial Waste

Section, added that the records of these facilities were carefully

checked, and they are recognized for their conscientious effort.

"It's appropriate to recognize companies which have devoted time and

money to achieve full compliance," notes Martyn. "You always hear

about the bad guys, and we thought it was time that you hear about the

good guys."

The idea for the Certificate of Recognition originated with the

Sanitation Districts' Industry Advisory Council, an advisory group of

20 representatives from different industrial sectors. The Council and

the Districts have felt it was important that industries with good

compliance records be recognized. The Recognition Program is now in

its eighth year.

"We hope this will become an award that is sought after by industry

and recognized by the public," says Sam Bell, Vice President of Metal

Surfaces, Inc. of Bell Gardens and chair of the Council. "It provides

further incentive for companies to meet Districts' limits and

regulations. The Sanitation Districts have always worked closely with

industry, and recognizing industry for conscientious compliance is a

further step to encourage companies to comply with regulations and

protect the environment."

Here are some of the powder coating units from the list of Industries

Recognized for Compliance with Wastewater Discharge Requirements for

2003

Downey

American Powder Coating & Painting, Inc

Bell Gardens

Enterprise Powder Coatings, Inc.

Monterey Park

Aero-Powder Coating, Inc. (4)

South El Monte

Abacus Powder Coating

eMachineShop.com World's First Online Factory Provides Instant Design

and Delivery Of Custom Mechanical Parts

Average 40

Hours of Engineering and Administrative Time For Single Custom Part

Reduced to Only 15 Minutes

MIDLAND PARK, N.J.—(BUSINESS WIRE)—June 21, 2004— eMachineShop (www.emachineshop.com)

is believed to be the world's first online factory enabling any

company, organization or individual to design, price, and instantly

order any mechanical part. From initial contact to placing an order,

the entire process takes as little as 15 minutes.

According to Jim Lewis, eMachineShop president, "Whether you are

designing a new part or are in need for more of an existing part,

getting custom parts is time consuming and costly. Until now, you had

to buy and learn expensive and complex CAD software, make technical

drawings, locate a machine shop, find a way to transmit the drawings

to the machine shop, discuss the design with an accomplished

machinist, sift through numerous price quotations, and eventually get

your part - often paying much more than necessary while adding weeks

of delay."

As value of manufactured goods output reaches $1 trillion every

month(a) online custom parts expected to grow exponentially

Mr. Lewis added, "eMachineShop is an innovative solution offering the

easiest, most cost-effective way to turn ideas into real 3D parts at

both prototype and production quantities. Whether for a new invention,

an existing product or construction of a space rocket, eMachineShop

revolutionizes the whole process. In just it's first two quarters of

operation, eMachineShop has produced parts for electronic panels,

enclosures, signs, scientific devices, parts for airplanes, cars,

motorcycles and trucks, ocean buoys, sensor mechanics and cameras.

"The value of manufactured goods in April, 2004 was $989 billion(a)*.

As the global economy continues to recover, online manufacturing

services such as eMachineShop have enormous potential. Barely out of

the starting gate, eMachineShop has already processed nearly 1,000

orders," Mr. Lewis commented.

eMachineShop at-a-glance

To begin, users download eMachineShop's free CAD software. During the

design phase, eMachineShop's automated machining expert analyses the

shape, material and finish to keep the user informed of any physical

limitations, thereby making it easy for engineers and non-technical

people to successfully design parts.

A built-in software expert system provides step-by-step guidance

through the process, often totally eliminating the need for expensive

engineering support and the associated delays, saving even more time

and money. For example, if a sheet metal bend is too close to an edge,

the software will advise the user in seconds.

A 3D preview helps visualize the final part before ordering. From the

customer's screen to delivery at the customer's door, eMachineShop

takes care of everything totally transparently. "Although not as fast,

it's almost like the transporter in Star Trek," said Mr. Lewis.

eMachineShop currently offers CNC milling, turning, punching,

blanking, laser cutting, plastic extrusion, thermoforming, tapping,

bending, water jet cutting, wire EDM and will soon add injection

molding. Surface finishes include brushing, plating, powder

coating, anodizing, polishing, grinding, and more. Materials range

from a broad selection of metals, plastics, woods, composites and

others.

Altair Nanotechnologies, Inc. Receives Grant From the U.S. National

Science Foundation

Company to Develop Nano-Structured Electrodes for Next Generation

Super Capacitors

RENO, NV -- (MARKET WIRE) -- 06/22/2004 -- Altair Nanotechnologies,

Inc. (NASDAQ: ALTI), a company engaged in developing high performance

materials and life sciences products using its pigment and

nanomaterials technology platforms, today announced that it was

awarded a grant from the National Science Foundation (NSF), effective

July 1, 2004. Under terms of the grant award, Altair will initially

receive $100,000 for work to be completed within six months of the

July 1, 2004, effective date. The grant is in support of a project

entitled "SBIR Phase I: Carbon-Coated Nano-Structured Electrodes for

Next-Generation Lithium-Ion Ultra Capacitors."

"We are pleased to announce Altair's first stand-alone grant,

spearheaded by our new board member, Dr. David King," said Dr. Rudi E.

Moerck, president of Altair. "The NSF's peer review process is

consistently recognized as the gold standard among government agencies

and private foundations in terms of setting the bar for quality

proposals and funding awards, making this grant further validation of

our nanotechnology expertise and uniqueness of our technology

platform. This grant builds upon the progress Altair has made in

bringing nanotechnology to super capacitor and battery applications."

Under terms of the Small Business Innovation Research (SBIR) Phase I

grant award, Altair will use the proceeds to fund joint development

work with Hosokawa Micron's Nano Particle Technology Center and

Rutgers University's Energy Storage Research Group. According to Dr.

Moerck, Altair's nano-sized cathode and anode materials are perfect

complements to Hosokawa's unique powder coating technology and

equipment and Rutgers' existing hybrid battery patents, advanced

battery design and testing expertise, all of which should provide for

the successful design and development of high-capacity, next

generation lithium ion power sources.

Third-party studies have shown that Altair's nano-sized lithium

titanate spinel battery material exhibited charge and discharge rates

up to 100 times higher than materials used in current commercially

available batteries. In the third quarter of 2003, Altair announced

that Telcordia Technologies (now Rutgers Energy Storage Research

Group) developed a non-aqueous asymmetric hybrid prototype battery

incorporating Altair's nano-lithium titanate spinel. The Rutgers

prototype battery, using Altair's nanomaterials, met the 'car of the

future' power assist battery requirement as published in The Journal

of Power Sources, 113 (2003) 62-71 and 115 (2003) 171-178. The

Rutgers' battery is the only prototype reported, to date, to meet

these Department of Energy (DOE) standards. Altair is currently in

discussions with Rutgers regarding commercialization and is providing

the group with additional nanomaterials samples for further

development work.

Nanomaterials are expected to provide an improvement in lithium ion

battery and super capacitor performance, making it possible to use

these systems in applications where immediate high power delivery is

necessary. Such applications include automobile batteries, electric

and hybrid vehicles. In addition to use in hybrid automobiles, nano-lithium

titanate spinel-based batteries may also be incorporated into

uninterrupted power supplies, military applications and specialized

uses, such as notebook computers, mobile phones, and a variety of

portable devices. Rapid charge/discharge times are important in all

these applications.

|

|

Quick Links www.ipconweb.com

|

Up Coming Events |

The Powder Coating Institute

is host of the world's largest powder coating conference and

exhibition to be held in Charlotte, North Carolina,

September 21 - 23, 2004. |

Your

comments suggestions contributions to our

website and the newsletter are always

welcome. Your emails, letters, calls and

visits are always encouraging.

Moderator |

|

|

|