|

India's Powder

manufacturing capacity.

(IPC exclusive)

The last year has been tough for the powder manufacturers all over

India. The sudden rise in raw material has certainly created an

disturbance in the existing equations. No amount of preparations could

have helped to absorb the Tsunami wave of price rise. The effect of

new tax structure (VAT) are yet to be estimated. The price of the

resins have increased substantially, while the prices rise in powder

paints is only a fraction of it

Despite of these negative forces an overall growth of 15 % to 20% is

suggested by most of the manufacturers. The larger players have

maintained there positions. They have the capacity to lower the

margins. Manufacturers with production figures less than a thousand

tons per year

could face more trouble in the future. With the bigger players adding

new manufacturing facility in the newer areas, it would be still

difficult for the smaller manufacturers who had, until now the extra

benefit of being available locally. Some companies have lowered

there margins to around 5 %. Going below that would be unwise, some

experts say.

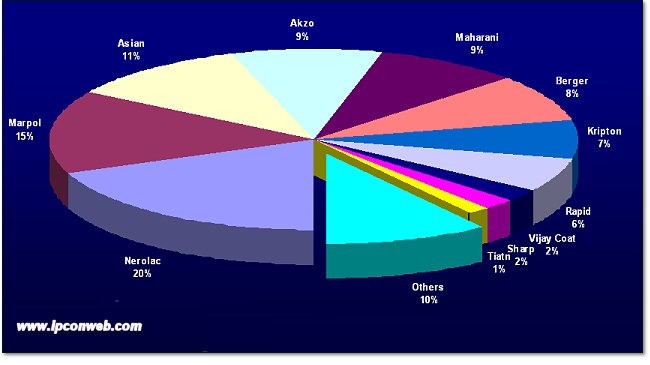

Polycoat powders continues to the leader in the market by producing

3750 tons of powder. Polycoat Powders Ltd., is an associate

company of M/s. Goodlass Nerolac Paints Ltd., occupying the No.1

position in the powder coating segment in India. Polycoat Powders Ltd.

is an ISO-9001 certified company and is engaged in the manufacture of

Thermosetting Powder Coatings since 1984.

Marpol occupies the second position producing 3000 tons of powder

paints in 2004-2005. Venugopal from Marpol said, "We have tried to maintain

our position in the market. Although there has been a sudden increase

in the price of the raw material, the effect has not been much since

we were prepared for it. Marpol is one of the leading

manufacturers of Powder Coatings in India with an installed capacity

of 4800MT per annum and a gross turnover of over US$10 million. They

offer over 1300 shades of powders in a range of chemistries, finishes

and gloss levels, for almost any type of interior or exterior

application.

Asian occupies the third position with a production of 2200 tons.

Akzo Nobel and Maharani contributed 1800 tons each. Rajendra Kardel of

Maharani Paints (India) Pvt. Ltd informed about the development

going on in high temperature resistant coatings and food grade

coatings developed at his company. Maharani Paints produces 150 tons

of powder per month which it around 1800 tons per year.

During an

internet chat, Manmohan Samantara informed that Titan produced 450 tons

of powder.

He predicts 900 tons for 2005-2006. With the last years figure of 250

tons, they have doubled the production.

Bijoy Mukherjee from Berger with a production figure of 1650 tons said,

"We target at 2150 tons figure for the next year". He said, "the

increase in raw material prices have certainly disturbed the market."

Deepak Madan from Kripton powders informed "Kripton produced 1400 tons

and in his email Ajit Gupta of Rapid Coat said "We manufactured

and sold 1,200 tons of Epoxy-Polyester powders in 2004-05". It had

contributed 900 tons in 2003-2004.

Officials at Vipraj were not interested in contributing any

information regarding their capacity or productions, however

last year, Ravindra Pandit informed that the Vipraj had produced 1000

tons. The reason for an iron curtain this year is difficult to guess.

Jayesh Ponda informed on telephone that Vijay Coat produced 425 tons

of powder during the last financial year. "Although the

competition is

high and rates of raw material have increased a lot we have tried to

maintain the quality", he said. Vijay enterprises was

incorporated in 1995 with a view to supplying quality Powder Coating

Materials to Indian industry.

Sharp Coating from Faridabad produced 420 tons while Titan paints

produced 250 tons. Besides these manufacturers there are several

manufacturers spread all over India. We were unable to contact all of

them. It could be assumed that they could be contributing around

2000 tons as their share.

There are several other small manufacturere who might be producing a

total of another 2000 tons of powder every year which adds up to a

final figure of 20,000 tons as the total powder produced and consumed

by the Indian Powder Coating industry during the financial year

2004-2005.

Moderator: We thank all those who helped to compile these details. We

will continue to conduct similar surveys and share the results with

you. Your suggestions and support are most welcome. While we have

used our best efforts in collecting and preparing the information we

do not assume, any liability for any loss or damage caused by errors

or omissions, whether such errors or omissions resulted from

negligence, accident or other causes. The subscribers may use their

own discretion while using the information.

Colors fading for

Indian Powder Coating Manufacturers Association.

Readers might be aware of an attempt made by some of the Powder

Manufacturers of North India to form an association.

In a meeting held

in January, they came together on common platform to discuss the

problem of growing prices and delayed payments.

After a few initial meeting it seems there were more argument than

discussions. During the last meeting some of the post holders

preferred to stay away and send there junior representatives to

attend. "Since the members are competitors, it is rather difficult

to agree on a common point, one of the member comments. Another attempt will be made on May 12th

to review the possibility of survival of the association.

Moderator's

message: We live in the age of information super highway. Our website has

already provided a common platform for the Indian Powder Coating

Industry. We can offer our unbiased stable platform to create a

virtual Indian Powder Manufacturers Association. Internet has already

changed the definition of words like communication, meetings,

conferences, relations and associations. On several

occasions we have helped our subscribers to communicate with each

other, have meetings, conferences, and business deals,

all in virtual space. If the powder manufacturers are

interested, we can work out on the structure of such a virtual

association which could include members and observers from all over

the nation..

| |

Infomercial

from Mitsuba Systems |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

Do feel free to contact us to know more

about how automation can reduce your powder coating cost. |

|

| |

|

|

| |

To know more about MITSUBA products

please visit www.powdergun.com

OR

Contact Us:

MITSUBA

SYSTEMS (I) PVT. LTD.,

34/H, Laxmi Industrial Estate,

New Link Road, Andheri (W),

Mumbai– 400 053. INDIA

Tel: 0091-22-2631 8633/2633 4735/56924151/52/53/54

Fax: 0091-22-56924154.

Email:

mitsuba@vsnl.com

|

|

| |

|

|

|

Sales

leads from ebiz newsletter

Our

website generates a number of sales leads every week. Such sales leads

can generate business for a several products. You must have observed

that we are eager to share such information with all the relevant

people. Unlike, other

business website

which restrict "supplier to customer" interaction, we promote this

activity. Our

website generates a number of sales leads every week. Such sales leads

can generate business for a several products. You must have observed

that we are eager to share such information with all the relevant

people. Unlike, other

business website

which restrict "supplier to customer" interaction, we promote this

activity.

Subscribe to the e-biz-newsletter, which contains information

about potential customers who are in need of products related to

powder coating.

To get this e-biz-newsletter, the user would have to pay a small

annual processing fee. Please send a DD of Rs 3000 (US$ 60) in favour

of "India Powder Coating" payable at Indore at the

contact

address

Some of the recent leads

generated during the last month are now also available on an

individual basis for Rs 500 or US $ 10 each. Here are some of them.

1, Plant required for coating steel bars in East India

2. Renovation of powder coating plant in Gurgoan, India

3. Powder Coating Plant required in Dubai.

4. Measuring instruments required in Automobile unit in North India

5. Powder paints required in Egypt.

6. Anodizing and Electro coloring plant required in Texas USA

7. Testing lab needed in Haryana.

8. Powder coating plant needed in Haryana.

|

Life after Indian Idol

There was a

time when Ravinder Ravi stood in line to buy the ration and pay

electricity bills, to save enough money to send his children to school

and to make ends meet.

"The struggle", he says, "made me weep." It was an overdose of

desperation that drove Ravi to catch the 10.30 pm bus from Ludhiana to

New Delhi on August 17, 2004 after he borrowed Rs 300 from a friend to

reach the gates of National Stadium, New Delhi where the auditions of

Indian Idol were taking place.

Two months after he was voted out, Ravi, the house painter from Ludhiana and the most loved and controversial contestant of Indian

Idol, is getting used to a new life.The changes are indeed immense.

For starters, Ravi has been approached by a leading paints company to

advertise their product. "I'm still negotiating," he tells us

excitedly.

Sources say the company is Nerolac Paints <more>

Despite rising costs, paint sector may post 5-15 pc topline growth

A ROBUST growth in the

housing sector and other end-user segments of the paint industry is

probably one encouraging sign in a scenario beset with rising input

costs and VAT hitches. Paint companies believe that while the

implementation of value-added tax augurs well for the sector, the

initial glitches could impact sales. However, continuing demand for

paints both in the decorative as well as the industrial segment is

seen negating any downturns. Overall the industry should be able to

post a 5-15 per cent increase in topline during the March 2005 quarter

despite a strong trend in crude and solvent prices. <more>

Industry keen to

strengthen trade with Pak

After India and

Pakistan signed a joint declaration focusing on trade in a big way,

business houses are looking to strengthen trade ties across the

border. With limited exchange between the two sides until now, the

size of official business is hardly anything to talk about. But that

may now change.

"A senior team from Berger Pakistan visited India two months ago. They

are keen to expand manufacturing facilities. We expect that we will be

assisting BP expand their facilities," said Ashwin Dani, Vice

Chairman, Asian Paints.

Asian Paints may soon share its expertise with a Pakistani company,

but the fresh start may not be just limited to manufacturing

businesses. Even the fashion industry is eyeing new markets thanks to

the open borders. <more>

US paint market predicted to grow

substantially

Impact Marketing Consultants predict that U.S. domestic consumption of

paint and coatings will grow by 4.5% annually in current dollars to

2008, reaching $20.1 billion, up from $16.1 billion in 2003. Unit

volume is forecast to grow at 3% annually during this time, from 5.06

to 5.88 bn litres. Powders, with consumption of 177 million kg valued

at $785 million in 2003, are forecast to grow by 5% annually for the

next five years. Also, radiation curing coatings are predicted to grow

above industry average. U.S. consumption of UV/EB formulations for all

applications is estimated at about 41 million kg valued at $350

million. Coatings, the largest segment, account for about 45% of all

uses. For more details click http://www.impactmarket.com

BASF increases capacity for vinyl

chloride copolymers

Coatings Magazine

E-news - April 7, 2005

BASF is increasing its production capacity for copolymers of vinyl

chloride to 12,000 tons/year at its Ludwigshafen, Germany, site. The

company will invest EUR 6 million to increase this capacity in

response to increasing demand for special coating systems. Vinyl

chloride copolymers are employed as binders in solvent-based coatings

applied to iron, steel, non-ferrous metals, plastics, mineral

substrates like concrete as well as for solvent-based printing inks

and marking paints. Their most important applications are in

anti-corrosion coatings such as shipbuilding and in packaging

printing.

Pigment Green 7: Hexachlorobenzene Update

Environment Canada has published the Prohibition of Certain Toxic

Substances regulations in the Canada Gazette, which includes

regulations for hexachlorobenzene for Pigment Green 7. Published on

March 9, 2005, the regulations come into effect May 15, 2005.

Section seven of the regulations lists the instructions companies must

follow.

Every manufacturer or importer of hexachlorobenzene or a product

mixture containing the material will have to submit the information

specified in Schedule Five within three months after the calendar year

during which hexachlorobenzene was manufactured or imported.

The first report must be submitted to Environment Canada by March 30,

2006.

For details, contact Dave Saucier, Inortech Chimie, an industry

stakeholder, at (905) 696-0954, e-mail dave@inortech.com. You can also

visit Environment Canada's web site.<more>

Tiger Drylac opens powder plant in BC

Coatings Magazine E-news -

April 7, 2005

Tiger Drylac Canada, Guelph, ON, is set to open a powder coating

manufacturing and research and development facility in Vancouver, BC.

Gabriele Grafinger, president, says that the new plant will help

improve service to Western Canada and allow for a quick turnaround of

custom match production.

Decorative paint looks and feels like leather, suede, woven fabric

Coatings Magazine

E-news - April 7, 2005

Akzo Nobel has developed what it says is the world's first decorative

paint capable of providing the look and feel of leather, suede or

woven fabric.

Alpha Touch is marketed under the Sikkens brand name. The application

method determines the finish you can achieve. An ordinary brush causes

the leather effect, a specially designed tool creates the look and

feel of textile. The product is used with a specially developed primer

and is available in 33 colours.

Rohm and Haas Powder Coatings opens Shanghai plant

Coatings Magazine

E-news - April 7, 2005

Rohm and Haas Powder Coatings announced the official opening of a new

powder coatings facility in Qingpu District, Shanghai, China. The

plant, which has received 5 million USD of investment and taken eight

months to construct, will produce a range of high quality powder

finishing materials for industrial and specialized applications in the

automotive, architectural, industrial goods, consumer durables and

general metal finishing industries. The 17,500 sq m plant houses a

full range of facilities including offices, research, quality control,

application laboratories, production facilities and a warehouse area.

Up to 100 employees will work at the plant when it is fully

operational.

Rohm and Haas Powder Coatings currently produces approximately 75,000

metric tons of powder coatings per year at seven plants in the US and

Europe. As the first Rohm and Haas Powder Coatings plant to open in

Asia, the new plant will make a significant addition to this capacity.

Bisphenol A ban proposed

in the USA

Coatings Flash -

April 25, 2005

A ban of Bisphenol-A (BPA), widely used in epoxy resin products, is

being proposed in the USA for certain products, after a recent

publication by Frederick vom Saal, Professor at the University of

Missouri-Columbia, in the monthly journal Environmental Health

Perspectives. Vom Saal reported about more than 95 independent

scientific studies backing his own findings, originally published

eight years ago, about the adverse health effects of BPA. After vom

Saal's first study, the chemical industry had conducted 11 studies and

found no problems. According to the new report, however, BPA is

extremely harmful in very low doses and has been linked to adverse

effects on male and female reproduction, altered immune system

function, behavioral changes, learning disabilities, brain damage and

an increased chance for certain cancers. Californian legislature is

now proposing a bill banning all use of BPA in products made for

children three years of age or younger.

Raw material costs reduce

net profits

Coatings Flash -

April 18, 2005

Hempel seized the opportunities presented by an expanding market

during 2004 to increase the volume of paints and coatings sold to 214m

litres. This is the highest volume ever sold by the Hempel Group.

Turnover grew by 9%, despite the fall of the US dollar, with the

growth coming from both Asia and Europe. "Rapid Asian growth had a

significant impact on our sales results, not only in marine coatings,

but also in coatings for bridges, cranes and containers. European

shipyards benefited from the full order books in Asia and picked up

extra business," says Hempel President and CEO Pierre-Yves Jullien. "Hempel

was able to capture this business with our strong worldwide network.

We were able to generate business in one part of the world and deliver

in another, in response to growing globalisation among our customers,"

he adds.

However, the financial result was disappointing relative to the growth

of the business. Operating profit fell by 23% to EUR 42.7 million,

from EUR 55.7 million in 2003. Net profit fell by 26% to EUR 12.2

million from EUR 16.5 million. Raw material prices have risen sharply

in 2004, mainly spurred by higher oil prices and strong demand for

various metals.

Akzo Nobel to acquire

Swiss Lack

Arnhem, the Netherlands, April 26, 2005 – Akzo Nobel’s Decorative

Coatings business has initiated the latest phase of its competitive

European expansion strategy by signing an agreement to acquire Swiss

Lack, Switzerland’s leading paint company. The deal – which will see

Akzo Nobel become the biggest coatings company in Switzerland –

includes taking over Swiss Lack’s brand portfolio, as well as its

large commercial distribution network.

Janesco acquires Derby

Plastics

Janesco Inc.,

parent company of Oshkosh Marine Supply Co., acquired molded and

injected plastics maker Derby Plastics Ltd. in order to diversify the

private company’s holdings and to explore potential crossover business

development. Janesco President Jim Janes said talks began almost a

year ago in regard to the acquisition of the Neenah-based company,

which was completed earlier this week, but he declined to release any

details of the sale or the purchase price.

The company now consists of a precision machine shop and powder

coating operation that serves AxleTech, Oshkosh Truck and other area

businesses. The company currently employs 34 people. <more>

Enviro-friendly

powder coating

Schiavello’s new

powder coat technology allows greater product design freedom and

reduces environmental impact.Schiavello Group has implemented the

world’s most advanced MDF (Medium Density Wood Fibreboard) powder coat

installation, working closely with DuPont.

The powder coating line applies specialised UV powder finishes on

various heat sensitive substrates, such as MDF wood and plastics,

providing cost effective, highly durable finishes that are

environmentally sound. Schiavello’s purpose built facility is designed

to accommodate the new process, based on successful installations in

Europe and America.

The facility features a dual system powder plant, setting new

benchmarks for coating performance, finish and repeatability on MDF

wood furniture products. The system enables the plant to cure powder

on wood utilising Ultraviolet (UV) curing and thermal curing, known as

Ultra-low bake (ULB).The Ray-Tec UV finish developed by DuPont meets

international standards (FIRA 6250 and DIN 68861) for hard wearing

horizontal work surfaces, such as desktops. <more>

New in Town - American

Precision Powder Coating

American Precision Powder Coating LLC has opened for business at 2750

Constitution Blvd. in Chippewa Township.

Owner Jim Verostek, a Monaca resident, formerly worked for American

Bridge Co. and L.B. Foster Co. He is a graduate of California

University of Pennsylvania and Duquesne University. <more>

|

Off

topic

Off

topic