|

India's Powder consumption in

year financial year 2005-2006

(IPC exclusive)

With the raw material prices stabalising, the powder prices too

have now reached a standstill level, unlike the sudden rise in raw material last

year which created an disturbance.

Based on the various resources we have referred to, and the discussions

we have with powder manufacturers, we have arrive at final figure of

34,000 tons as the total powder produced

and consumed by the Indian Powder Coating Industry during the

financial year 2005-2006.

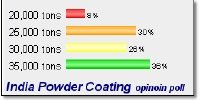

While most of the manufacturers indicated the total figure to be around

20-25 thousand tons, our viewers vote pointed in the correct direction. The

opinion poll on our website projected a very realistic picture of the

market. See the poll results in the adjacent graph. While most of the manufacturers indicated the total figure to be around

20-25 thousand tons, our viewers vote pointed in the correct direction. The

opinion poll on our website projected a very realistic picture of the

market. See the poll results in the adjacent graph.

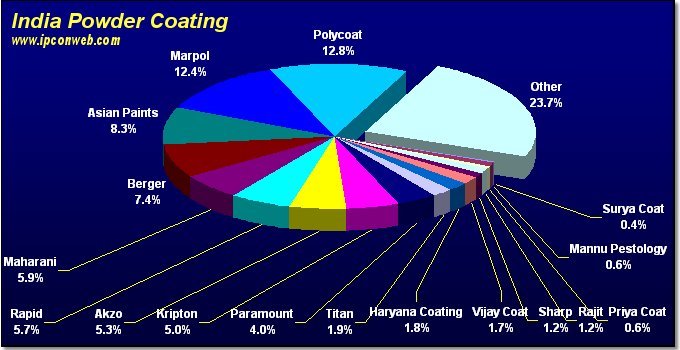

Viewer may notice a large percentage (23.7 %) under the category of

"Others". Neglected earlier,

there are several small manufacturers who might be producing a

total of another 6000 tons of powder every year.

Also added to it are about estimated 2000 tons of powder produced by a few

companies who have avoided revealing there production figures due to certain

policy matters. So a total of 8000 (23.7%) tons is put under the category of

"Others"

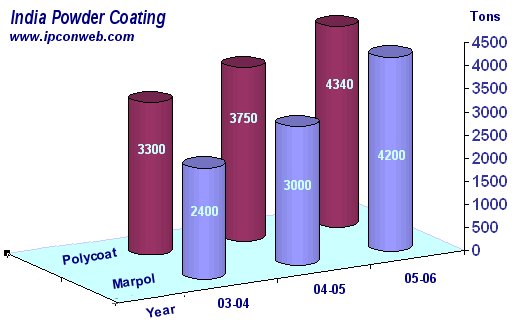

Once again Polycoat powders continues to be the leader in the market by producing

4350 tons of powder. Congratulations Polycoat. Amrit Rekhi

of Polycoat said

"The Powder coating market has shown good growth

last year. In the past white goods were the main drivers for growth however

this trend has now changed and new growth drivers have evolved. The current

market growth is being driven by segments like Auto ancillaries,

Architectural and Engineering goods. These segments would continue to lead

the powder market to new highs in the near future...."

Mr Venugopal from Marpol informed us that the company has produced

4200 tons of powder in 05-06 Marpol's production has been steadily rising

towards the number one position (See the adjacent graph). He said

"There are various dynamics involved in

the production figure, however, every year we are growing by more than 35

percent." Mr Venugopal from Marpol informed us that the company has produced

4200 tons of powder in 05-06 Marpol's production has been steadily rising

towards the number one position (See the adjacent graph). He said

"There are various dynamics involved in

the production figure, however, every year we are growing by more than 35

percent."

Commenting on the Exports, Mr. SV Prasad, said

"Chinese

aggressive pricing policy is creating problems for Indian manufacturers to

explore the export markets . They have the support of the government which

we don't have . In fact Powder coating is not covered under the SION of

advance license DGFT norms. The Industry should represent to the governement

for encouragement of exports"

He further said,

"I admire you for the efforts

you are making. Definitely one day all the people in the industry will

acknowledge that

Mr Ashay Aggrawal of Asian Paints said,

"We are close to 2800 tons with about

30 percent growth. Commenting on the total market, he said "A lot of smaller

players are adding to the field and the total size could be around 25000

tons. We had a production limitation till last year, This year our new

plant has come in operation in Baddi. We have to see the impact of it in

2006-07. Commenting on the production figures, he said we have a certain

segment to look for, and it is not a race where we have to run over each

other."

Mr Bijoy Mukherjee informed us that Berger produced 2500 tons of powder.

Mr Chummar, Vice President of Maharani Paints said

"We produced 2000 tons of

powder during 2005-2006. He estimates India's total powder production figure

to be 20,000 tons. The powder market has not grown much. He said we have

developed the food grade and the high temperature resistant powders.

Regarding the low bake powder he said "The climatic condition of our country

doesn't permit us to produce and transport such powders..

Mr Ajit Gupta of Rapid Coat Powder Coating from Delhi said

"We produced 160 tons of powder a month".

This

totals up to around 1700 tons. He said,

"Growth was good as compared to last year.

Everybody is growing and the industry must have grown by 25 percent"

Mr

Gupta also finds our website very useful. "When people ask me various

questions on powder coating, I just divert them to India Powder Coating", he

said.

The next position is occupied by Akzo nobel. Mr Ravi from Akzo Nobel informed a figure of 1800 tons for the last

financial year. He estimates a growth of 15% in the Indian powder market

which could be around 20,000 tons in the calendar year. He

specifically mentioned the change in growing pattern this time. The growth

is not restricted to particular segments but its a growth in totality.

Kripton produced 1700 tons, informed Mr. Deepak Madan.

Mr Tripathi, from Paramount was rather dissatisfied with this analysis He

said "Some the figure given by the manufacturers are very unrealistic and

exaggerated. When you club my genuine figure with the others it is no more a

true analysis. This forum would not remain a realistic forum if

people use it with a marketing angle. He suggested that an independent survey should be

conducted, and then the analysis will be more authentic. You should not allow

your site to be use for marketing tool for some companies".

He confirmed

Paramount produced 1350 tons.

In his email, Manmohan Samantra, General Manager, Titan Paints and Chemical

Ltd said "with a 50-50 share in the Job market and the

OEM market, in 05-06

we sold 650 tons of powder", His estimate of India's total production is

around 25,000-30,000 tons.

While Tapan Kumar Dhal who is Manager Technical assesses Indian Powder

coating market size as just 0.5-1% of global market. His estimates of the

Indian powder production is 35000 tons, and India could have 150000 powder

coating machines to spray it.

Mr

Satish Gupta from Haryana Coatings Pvt. Ltd. with the brand Name "Tuffcoat"

informed a contribution of 600 tons. While Mr Jayesh Ponda of Vijay Coat

gave his production figure as 575 tons.

Mr Kuldeep Verma said Sharp Coatings made 400 tons. Same was the figure for

Rajit Powders.

Dr Mohammad Nazimuddin said Rajit Paints manufactured 400 tons and the

powder goes to Medium size OEMs. His estimate of yearly production is 25000

tons. The company has a capacity of 60 tons per month and plan for 100 tons

per month in the next year.

Rajesh Arora of Priya Coat informed the company made 200 tons in 05-06.

While Mr Surendra Mittal of Surya Coat contributed 140 tons. His powder goes to

India and Nepal too.

Mannu Pestology produced 200 tons said Mr. PL Aggrawal .

Our Chinese subscribers are also keenly interested in the India Powder

Coating Market.

Talking to some of our Chinese subscribers which include powder

manufacturers, the estimated Chinese market size is around 400000

tons. The Indian

market is not even 10 % of the Chinese market. Another Chinese subscriber

said, "here in China, there are 2000 manufacturers.

Moderator: We thank all those who helped to compile these details. We

will continue to conduct similar surveys and share the results with

you. Your suggestions and support are most welcome. While we have

used our best efforts in collecting and preparing the information we

do not assume, any liability for any loss or damage caused by errors

or omissions, whether such errors or omissions resulted from

negligence, accident or other causes. The subscribers may use their

own discretion while using the information.

|

IPC Classified |

Gallant

Equipment Pvt. Ltd.

GALLANT is a leading Manufacturer & Exporter of 100 kV Electrostatic

Powder Coating Equipment (Manual & Automatic), Curing Oven Electrical,

Gas & Diesel Fired (Heat Exchanger), Coating Booth, Recovery Cyclone

Liquid Painting System, Fusion Bonded Epoxy & Teflon Coating system for

Manual Batch to Automatic Conveyorised Plant in turnkey basis

Our success voyage has been consistent and has gained momentum over the

years. Our belief that needs expand and diversify with time, guides us

to keep pace with change. Thereby channelizing our resources in

production, marketing and distribution likewise. Continuous quality

improvement is a commitment toward the goals of satisfying our service

receivers, providing more involvement and opportunities for employees,

and delivering services with speed, accuracy low cost, reliability,

flexibility, understanding and personal attention.

( Dealer / Distributor Enquiry Solicited in Unpresent Area)

For details contact:

Gallant

Equipment Pvt. Ltd.

( Formaly New

Tech Coating)

36/69,Jyotish Roy Road Kolkata-700053,W.Bengal,India

Phone:+ 91-033- 32955075,Fax-+ 91- 033 - 24036196

Cell : 09830080783 / 09830295136

Email :

newtech@powdercoatindia.com \

newtech2k@sify.com

Website :

www.powdercoatindia.com

|

Your message

here

You can reach thousands of people thorough our classified ads. Place

your own classified text ads. or messages here Just for Rs 500 (USD

10) only

Contact the moderator for details

India Powder

Coating

Vivek Soley

3, Lalaram Nagar, Indore, 452001 MP India

Phone 91 731 2492291

Mobile 9826297112

emails: viveksoley@hotmail.com

, viveksoley@ipconweb.com

,

indiapowdercoating@yahoo.com

|

Vijay

Enterprises Pvt. Ltd. Vijay

Enterprises Pvt. Ltd.

Vijay Enterprises is a leading manufacture of powder coating materials (PCM)

in India. VIJAY COAT today stands as a Reliable source of High Quality

and Durable Powder Coating materials at very reasonable prices. Vijay's

PCM find extensive application for industrial and other demanding

applications. Vijay enterprises was incorporated in 1995 with a view to

supplying quality PCMs to Indian industry. Vijay's manufacturing set up

is equipped with best machines from M/s Buss AG Switzerland who are

world's largest manufacturer of Powder Coating Machines. Vijay has now

established itself and earned a name for its quality supplies and prompt

delivery at very economic prices. VIJAY has multi-locational production

facilities near Ahmedabad in western India and at Silvassa in the U T of

Dadra & Nagar Haveli, 200 Kms off Mumbai. This makes it a competitive

source of PCMs to all customers.

Vijay Enterprises Pvt. Ltd.

Admin. Office :

103, Gita Bhavan, 1st Floor, Opp. Vijay Transport,

Narol Char Rasta, AHMEDABAD 382 405.

GUJARAT. INDIA.

Telephone: +91-79-2532 9057, 25329374,Fax: +91-79-2535 9481

Email:

jayesh@icenet.net

web:

vijay-powdercoat.com |

| |

|

|

| |

Infomercial from

Mitsuba Systems

|

|

| |

EFFICIENCY METER |

|

| |

|

|

| |

|

|

| |

For more Mitsuba products information please visit

www.powdergun.com

OR

Contact Us:

MITSUBA SYSTEMS

(I) PVT. LTD.,

34/H, Laxmi Industrial Estate,

New Link Road, Andheri (W),

Mumbai– 400 053. INDIA

Tel: 0091-22-2631 8633/2633 4735/56924151/52/53/54

Fax: 0091-22-56924154.

Email:

mitsuba@vsnl.com

|

|

| |

|

|

|

Infomercial

from Mercury Specialty Resins Infomercial

from Mercury Specialty Resins

Product Data Sheet from

Cure Coat CC 1314

General Description:

CC 1314 is a Carboxylated Polyester Resin designed for Hybrid

System. When used with epoxy resin at 50/50 ratio. This gives a good

flow with an excellent over baking resistance with mechanical

properties.

Polyester Properties:

|

Appearance |

Pale

Flakes |

| Colour

(Gardner) |

Max.

4 |

| Acid

Value (mg koh/g) |

75 ± 3 |

|

Viscosity at 175° |

70-100

P |

|

Reactivity at 180° C (50% GT 7004) |

200 ± 25

seconds |

| Glass

Transition Temperature °c |

>55

|

Guide Formulation:

| Material

|

CC1314

|

GT 7004

|

Blank

Fix |

Flow Aid |

Benzoin |

Phil

Black Pigment |

| %

|

30 |

30 |

36.6 |

1.0 |

0.4 |

2.0 |

Application

Properties:

| Baking

Schedule |

Film

thickness |

Gloss

|

| 180° C /

l0 minutes, Metal Temperature |

50-60

microns |

95% at

60° |

Mechanical Properties:

| Impact:

Forward |

Reverse

|

Bend

Test |

Cross

Hatch Test |

| 80

Kg cm minimum |

80 Kg cm

minimum |

Passes,

2mm |

Passes (GT

=0) |

Storage: Keep away from heat source and direct sunlight, Store below 30°

C.

Packing: 25 Kg laminated . woven sacks

The information given above is true and accurate to best of our

knowledge, however we do not take any warranty or liability arising out

of its use, since the condition of use is beyond our control.

Manufactured By:

Mercury Speciality Resins

GAT No. - 5511A, Gonde

Tal- Igatpury

Dist Nahsik 422403

Email mercury@rediffmail.com

|

Akzo Nobel Coatings acquires

Czech paint company

Akzo Nobel's Coatings business is continuing to build its position in

Central Europe having signed an agreement to acquire Balakom a.s., one of

the leading paint companies in the Czech Republic. Based in Opava in the

Czech Republic, the purchase of Balakom will substantially increase Akzo

Nobel?s domestic market share and provide a solid base for further

expansion. Today Balakom, which was established in 1907, has 183 employees

who produce paints, varnishes, enamels and lacquers, as well as powder

coatings. Sales, which are mainly in the domestic market, totalled EUR 16

million in 2005. ?Strengthening the presence of our coatings activities in

Central Europe is a key element of the company?s global expansion strategy

and this deal makes sound business sense on a number of levels,? explained

Akzo Nobel CEO Hans Wijers.

|

Surface Chemistry of

Carbon Black

All carbon blacks have chemisorbed oxygen complexes (i.e.,

carboxylic, quinonic, lactonic, phenolic groups and others) on their

surfaces to varying degrees depending on the conditions of manufacture.

These surface oxygen groups are collectively referred to as volatile

content.

The coatings and inks industries prefer grades of carbon black that are

acid oxidized. Acis is sprayed in high temperature dryers during the

manufacturing process to change the inherent surface chemistry of the

black. The amount of chemically-bonded oxygen on the surface area of the

black is increased to enhance performance characterstics.

Carbon black imparts pigmentation to products. Pigmentation refers to

the color of a material or to carbon black's ability to deliver color to

a final product. Different formulations of carbon black can influence

aspects of pigmentation.

Jetness, undertone and gloss are important in products such as inks,

paint, lacquers, enamels and industrial finishes.

UV Protection, infrared absorption and heat protection are important in

outdoor applications such as primers for cars or boats, as well as

industrial coatings that are exposed to weather. Carbon Black protects

products from ultraviolet light because of its ability to absorb and

dissipate light rays. UV rays are harmful because they cause product

breakdown, making UV protection especially important in products used

outdoors.

Author: Mayur

Palta, VP, Industrial Chemicals - Palta Fertilizers & Chemicals

|

Goa-Kundaim: Major Fire in Berger

Paints Factory - Loss in Crores

PONDA, APRIL 28 — Paint, machinery and property estimated at crores of

rupees were gutted in a major fire at the Berger Paints factory at the

Kundaim Industrial Estate on Friday morning.

According to reports, the fire broke out at about 11 am, when employees were

at work. An employee, Tulsidas Naik, sustained minor injuries in the process

and was shifted to a private hospital.

Within minutes, the fire engulfed one of the two single-storeyed buildings,

which housed paints and machinery.

Fire brigades from Ponda, Mapusa, Bicholim, Valpoi, Verna, Margao, Old Goa,

Panjim and from the Navy at Vasco rushed to the site, as fire-fighters

battled for 7-8 hours to control the fire.

Priol MLA Vishwas Satarkar, Panjim Additional Collector G P Naik, Ponda

Deputy Collector Deepak Dessai, Ponda Mamlatdar Gourish Shankhwalkar, Ponda

DySP Mohan Naik, PI Manjunath Dessai, Director of Fire Services Dr P K John

and other officials visited the scene to take stock of the situation., <more>

Berger to raise paints prices

Calcutta, May 17: Berger Paints India Ltd will raise its solvent-based

paints prices by 3-4 per cent by the end of this month, managing director

Subir Bose said here today.

Solvent-based paints contribute nearly 55 per cent of Berger Paints’

turnover of Rs 1,100 crore as in 2005-06.

“That’s the impact of increased crude oil and petroleum product prices on

our bottomline. We have decided to pass it on to the customers,” Bose said.

<more>

Asian Paints quarterly earnings

dip

Calcutta, May 10: Asian Paints Ltd’s earnings have suffered a setback in the

fourth quarter of last fiscal. It has reported a 50.65 per cent drop in net

profit at Rs 20.28 crore compared with Rs 41.10 crore in the same period

previous fiscal.

The quarterly profits fell despite a 25.81 per cent rise in income (net of

excise) during the period to Rs 578.93 crore from Rs 460.13 crore a year

ago.

For 2005-06, the company posted a net profit of Rs 186.78 crore, marginally

up from Rs 173.48 crore in 2004-05. <more>

Asian Paints commissions new

manufacturing facility for industrial coatings

Asian Paints, based in Mumbai, India, has commissioned a new manufacturing

facility at Baddi in Himachal Pradesh through its wholly owned subsidiary,

Asian Paints Industrial Coatings Limited (APICL). This is Asian Paints’

first Greenfield facility commissioned exclusively for manufacturing powder

coatings. The new facility is expected to cater to the growing demand for

industrial powder coatings and will initially have a capacity to produce

1,200 million t/a. The total capacity will be scaled up to 5,000 million t/a

in due course. The plant at Baddi, HP is Asian Paints’ seventh paint

manufacturing facility in the country and the second manufacturing facility

for powder coatings. The other powder coating facility is located at Sarigam-Gujarat.

VIP Industries Q4 net drops 13%

The Board of

Directors of V.I.P. Industries Ltd., the largest luggage manufacturer in

Asia, on Tuesday considered and adopted audited results for the fourth

quarter and full year ended March 31, 2006. A dividend of 20% (Rs2 per

share) was also declared.

VIP. Industries has set up a new plant at Haridwar in Uttaranchal with

injection moulding, frame manufacturing, anodizing and powder coating

facilities. The installed capacity of this plant is about 2mn pieces per

annum and has started commercial production from April 2006. This Plant will

primarily cater to the Civil Market (Trade) and will lead to substantial

income tax and excise duty benefits to the company. The company has incurred

a capex of Rs. 16 crore on this facility.

“We have been working hard to protect our trademarks and have recently won a

case in the Delhi High Court, restricting three traders in the National

Capital Region from misusing our trademarks and copyrights. This is the

first such victory for the company, and we hope to use this as a starting

point to target retailers misusing the V.I.P. name,” said, the Chairman.

Reichhold Announces List &

Off-List Price Increases on Polyester Powder Coating Resins; Effective June

15

RESEARCH TRIANGLE PARK,

N.C.--May 24, 2006--Reichhold, Inc. announced price increases today of $0.04

- $0.08 per pound on all FINE-CLAD(R) polyester powder coating resins sold

in North America. These increases are effective for all orders shipped on or

after June 15 for both list-priced and off-list priced products.

"We have found it necessary to increase our selling prices on these specific

products due to recent escalations in raw materials and increased

transportation costs," said Reichhold Specialty Resins Business Manager Bob

Gilliam.

"We appreciate the understanding of our customers as we strive to provide

technically superior products within a volatile raw material environment,"

Gilliam said. "We continue to invest in our manufacturing capabilities and

new product development to meet customer needs both today and into the

future," he concluded. <more>

DuPont to Build New Plant in

China

DuPont's New Industrial Coating Plant in China to Employ 250 and Open in

2007

WILMINGTON, Del. (AP) -- Chemicals maker DuPont said Tuesday it began

construction of a new coatings plant in Shanghai, China and expects to open

it in late 2007.

The plant will employ 250 people and serve automotive and industrial markets

in China. The cost or size of the factory was not disclosed.

The company already operates a plant in Changchun to make advanced

automotive finishes, where it invested $20 million in 2004. It also operates

four powder coating plants as well as a refinish technical center and

several training and service centers.

Shares of Dupont rose 15 cents to $44.68 in afternoon trading on the New

York Stock Exchange. <more>

ICI Dulux expands into Qatar

Dulux paints, part of the paint business ICI Paints, is expanding in the

Gulf. A Dulux Decorator Centre (DDC) has just opened in Qatar, and another

will open in Oman shortly.

"ICI Dulux saw phenomenal growth in 2005 and eight DDC's are now up and

running in the UAE. Last year saw the launch of a DDC at Better Life and

IDdesign inside Dubai's Mall of the Emirates, the first centre to open in a

UAE shopping mall,' said Philip Mathew, general manager, Al Gurg Leigh's

Paints, which manufacturers Dulux in the UAE. <more>

DSM to expand its production capacity of polyester powder coating resins

DSM Eternal Resins decided to expand their production facility for polyester

powder coating resins in Kunshan, China. The new facility is expected to

come on stream in the fourth quarter of 2006. In addition DSM Resins Far

East (Ping Tung, Taiwan) decided to invest in the further measures to

avoid a bottleneck in its powder coating resins production. This capacity is

expected to come on stream as of Q3/2006. Dimitri de Vreeze, Business Unit

Director of DSM Coating Resins, comments: "The expansion is of strategic

importance and necessary to maintain DSM's leadership position in the

Asian and powder coating resins markets. (...) It represents a further step

towards the realization of DSM's ambition to double its total turnover of

USD 500 million in 2004 in China to USD 1 billion by 2010."

EPA withdraws plans to exempt

electroplating sludges from RCRA

The U.S. Environmental Protection Agency (EPA) has withdrawn plans to

propose a rule exempting recycled electroplating sludges known as F006 waste

from the Resource Conservation & Recovery Act (RCRA), following reported

White House Office of Management & Budget (OMB) pressure for the agency to

address all waste recycling under its forthcoming definition of a solid

waste (DSW) rule, according to the Superfund Report

Nissan launches self-repairing

paint

Japanese carmaker Nissan has introduce what it has claimed to be the world's

first clear paint which repairs scratches on painted car surfaces, including

the scuffs caused by car-washing machines and driving off-road.

The X-Trail sports utility model has been chosen as the first car in the

range to utilize the coating, which contains a highly elastic resin. This

stops the scratches from affecting the inner layers of a car's paintwork. <more>

Kemira: Alcro-Beckers to build a new paint plant in Sweden

Alcro-Beckers AB, part of the Finnish Tikkurila that is responsible for the

Kemira Group's paint business, has agreed to sell its factory site located

near the centre of Stockholm to

Skanska. The preliminary price has been set at EUR 36.3 million (SEK 340

million). Alcro-Beckers has been producing paints on the L?vholmen site

since 1902. The present paint

production will be transferred mainly to Nykvarn, some 40 km to the south of

Stockholm, where a new, modern paint plant will be erected next to the

company's existing logistics

centre. This investment amounts to EUR 16 million (SEK 150 million), and the

transfer of production is scheduled to take place during the first half of

2008. Other functions of Alcro-

Beckers will continue to be located in the Stockholm area.

Advances in rail vehicle

coating

Coatings Flash - May 22,

2006

The detailed programme of Ecolromat 2006, the European congress on the

coating of rail vehicles, has been completed and is available online at

http://www.coatings.de/events/ecolromat/. Four years after the previous

event, railway operators, engineering and coating specialists as together

with paint and raw material manufacturers are again invited to to Mulhouse/France

on 19 and 20 October to exchange ideas about optimised coating processes for

rail vehicles. Special emphasis is laid on innovative VOC-reduced coatings

systems, including, e.g., UV-curing, VOC-free anti-graffiti clear coats.

Another focus will be the adaption of successful automotive technologies for

rail vehicle coatings and protective coatings with a film thickness of less

than 5 µm based on nanotechnology. The entire meeting will be simultaneously

translated into German, English and French.

Corro-Coat buys Chemrez in swap

Publicly-listed Corro-Coat Inc. yesterday said in a disclosure to the

Philippine Stock Exchange that it acquired 100 percent of bio-diesel

producer Chemrez Inc., a sister company, through a share swap agreement.

The acquisition effectively completed the backdoor listing of Chemrez, which

had aimed to list its shares in the stock market.

Corro-Coat, a subsidiary of D & L Industries, is owned by the Lao family. D

& L introduced powder coating in the Philippines in 1981 and spun off the

business in 1989 to another company, Corro-Coat. The company listed its

shares at the PSE in December 2000.

The board of Corro-Coat also approved an increase in the company’s

authorized capital stock to P2 billion from P1 billion and change in the

corporate name of Corro-Coat to Chemrez Technologies Inc. <more>

BASF: Successful start to 2006

For the first quarter of 2006, BASF announced a top performance. At EUR 12.5

billion, first-quarter sales were 24 % higher than in the same period of

2005. Disregarding currency effects, in particular due to the appreciation

of the U.S. dollar, sales increased by 20 %. Income from operations (EBIT)

before special items rose by 19 % compared with the first quarter of 2005 to

EUR 1.9 billion. First-quarter EBIT after special items rose by 23 % to

EUR 1.8 billion. The financial result declined by EUR 24 million to EUR 21

million. Income before taxes and minority interests rose by 21 % to EUR 1.9

billion. The tax rate was 46 %

compared with 40 % in the first quarter of 2005. Net income increased 10 %

to EUR 950 million

Crime

PRINCETON

A burglar entered an unlocked shed in the 26200 block of Southwest 130th

Place between 8 and 9:20 a.m. May 18, stole $2,750, two air-guns, tools and

a powder coating machine valued at $12,800 and left behind a pair of yellow

rubber gloves, which police took as evidence.

PRINCETON

A vandal sprayed something on a 2005 Nissan in the 11900 block of Southwest

81st Road, causing the paint to peel off, between midnight and 5:30 a.m. May

19. <more>

|