|

| |

Infomercial from

Mitsuba Systems |

|

| |

|

|

| |

Sampling Cup for

Powder Coaters

|

|

Sampling Cup for Powder Coaters

Sampling is now easy and time efficient process with the new Mitsuba

sampling cup.

Mitsuba sampling cup is available in capacity of 500 gms. It can be

fit with Mitsuba as well as with any other brand of gun. With

sampling cup you have flexibility to use your gun as sampling gun as

well as full scale production system.

Today’s powder coating set up needs flexible systems to deliver what

the customer demands, when the customer demands it. Approval of

coated samples form customer is crucial and an important step in any

coating company. At present, a coater needs to clean entire hopper

for coating even a small sample. And if the quantity is small, he

needs to test the sample by putting powder pump directly in to the

powder box. This method has high risk of irregular powder flow,

which will result in rejection of the sample. Besides, this is time

consuming and makes your shop floor dirty.

With Mitsuba sampling cup, coater can save time and money. To watch

the video of the Sampling Cup in action please follow the link:

https://www.youtube.com/watch?v=AMfjlLBHKnc

To know more about Mitsuba products please visit

www.powdergun.com or

contact us at:

Mitsuba Systems (India) Pvt Ltd,

34/H, Laxmi Indl Estate,

New Link Road,

Andheri (W),

Mumbai - 400 053.

Tel: 2631 8633 /66924151/2/3.

Fax-66924154

Email:

mitsuba@vsnl.com

Website:

www.powdergun.com

|

| |

|

|

Infomercial from Vijay Enterprises Pvt. Ltd

Vijay Enterprises Pvt. Ltd.

Vijay Enterprises is

a leading manufacture of powder coating materials (PCM) in India. VIJAY

COAT today stands as a Reliable source of High Quality and Durable

Powder Coating materials at very reasonable prices. Vijay's PCM find

extensive application for industrial and other demanding applications.

Vijay enterprises was incorporated in 1995 with a view to supplying

quality PCMs to Indian industry. Vijay's manufacturing set up is

equipped with best machines from M/s Buss AG Switzerland who are world's

largest manufacturer of Powder Coating Machines. Vijay has now

established itself and earned a name for its quality supplies and prompt

delivery at very economic prices. VIJAY has multi-locational production

facilities near Ahmedabad in western India and at Silvassa in the U T of

Dadra & Nagar Haveli, 200 Kms off Mumbai. This makes it a competitive

source of PCMs to all customers.

Vijay Enterprises Pvt. Ltd.

Admin. Office :

103, Gita Bhavan, 1st Floor, Opp. Vijay Transport,

Narol Char Rasta, AHMEDABAD 382 405.

GUJARAT. INDIA.

Telephone: +91-79-2532 9057, 25329374,Fax: +91-79-2535 9481

Email:

jayesh@icenet.net

web:

vijay-powdercoat.com |

|

Job Opportunities |

FREE

Often we receive emails with no contents, but a resume word document

attachment.

This column could be of use for such people, those who are looking our for better prospects.

Use this space to publish your mini resume in the format given in

the adjacent column. You may or may not reveal your identity. Send us

these details and we will put it this column

|

Name: Bharat Bhushan

Date of Birth: 1-1-1954

Email :

bbhushan2000@gmail.com

Link to resume:

Bharat Bhushan |

Name: MOHAMMED EL-SHERPENY

Date of Birth: 26 / 02 / 1983

Location Egypt

Current job: Geochemistry in Electrostatic Powder Coating.

Email :

geochemistry_mohamed@yahoo.com

Link to resume:

MOHAMMED EL-SHERPENY |

|

|

Name: S.P.Pawde.

Current job:Powder Coating

Link to resume:S.P.Pawde.

|

|

IPC Classified |

Your message here

You can reach thousands of people thorough our classified ads. Place

your own classified text ads. or messages here Just for Rs

500 (USD 10) only

Contact the moderator for details

India Powder

Coating

Vivek Soley

3, Lalaram Nagar, Indore, 452001 MP India

Phone 91 731 2492291

Mobile 9826297112

emails:

viveksoley@hotmail.com ,

viveksoley@ipconweb.com ,

indiapowdercoating@yahoo.com |

Hopping your way to the right job

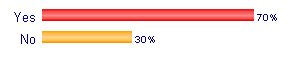

IPC Opinion poll results.

Job hopping catalyses the

spread of knowledge in the economy and encourages the growth of new firms in

similar businesses.

Long ago, A person and a Company had a life time association. Working for a

span of 20-25 years with the same company, was a routine way of spending

life. Your parents must have joined a company in there teens and retired

from the same.

Not any more.. An employer wrote to us ...."Every day for the last four

months I have been hiring. I come to office each day, hassle my recruitment

team, agencies and consultancies for resumes, perform interviews and

negotiate salaries."

“Today, job hopping is not only tolerated, it is encouraged,” Job hoppers,

it is now believed, lead to the spread of knowledge and, as a result,

innovation. This is obvious when it comes to hi-tech industries. Even the

foreman on the shop floor could bring along with him time and cost saving

practices when he switches companies. In other words, job hopping catalyses

the spread of knowledge in the economy and encourages the growth of new

firms in similar businesses.

Most of the industries in the powder coating field are facing this new

concept.

The result of the opinion poll on our website need no further comments. Job

Hopping will continue.

Every person has a right to rise to the optimum

economic level, however, one must take care not to cross the

thin line of business and human ethics while hopping.

Wagner in India

Mumbai, 27th February 2008

Wagner

has recognized the huge potential in India and has setup a direct office in

Delhi. The launch program was held at the ITC Maratha in Mumbai on 27th

February 2008. In the presence of distinguished guests who represented a

wide spectrum of the coating industry, Mr. Marzio Giardini (MD, Wagner

Industrial Solutions) declared it open. The guests included paint and powder

suppliers, end users and distributors. Wagner

has recognized the huge potential in India and has setup a direct office in

Delhi. The launch program was held at the ITC Maratha in Mumbai on 27th

February 2008. In the presence of distinguished guests who represented a

wide spectrum of the coating industry, Mr. Marzio Giardini (MD, Wagner

Industrial Solutions) declared it open. The guests included paint and powder

suppliers, end users and distributors.

Wagner is now distributed in India through

Epcoat Surface Systems in the Western and Southern region.

The launch program included a presentation by Mr.Franz Maier (VP –

International Distribution). He mentioned that the entire market for the

coating industry is approximately 1 billion euros. This was further split

into 74% for the powder industry and 26% for the wet coating industry. He

then went onto mention the ambitious plans for Wagner in India and the

setting up of a sales office in Pune along with the head office in Delhi. He

also introduced the team in India and the team in Germany that will backup

the sales team here. The complete range of Wagner products for the liquid

and powder coating industry were also explained in a nutshell.

Mr.Imtiaz Ahmed (National Sales Manager) with his vast experience in the

coating industry will head the team. He mentioned that Wagner will work on

building its distribution network in the first year. Wagner is also in the

search for distributors in the regions that are not covered yet. He said

that this will give them the much needed penetration in the vast Indian

coating market.

Mr.Rajendra Mainkar (Regional Sales Manager-West) claimed that Wagner will

build its network with a strong focus on service. Wagner will train all its

distributors with service capabilities to cater to customer’s needs. They

will be supported with a service setup from Wagner for problems that they

may not be able to handle. Mr.Shrikumaravelu (Technical Manager) made a

presentation on the capabilities of Wagner in building systems with varying

degrees of automation worldwide. There was also a video on an alloy wheel

coating line that Wagner has set up. Incidentally Wagner is a world leader

in coating alloy wheel rims due to their extensive experience in powder as

well as wet coating.

This was followed by an interactive Q&A session with some intuitive

questions on Wagner’s plans and all participants wishing Wagner the very

best. In conclusion it can be said that Wagner is looking to cement its

place in the Indian coating market as a major player. In the words of

Mr.Giardini, “We have a focused plan for the next 5 years where we would

like to make Wagner a top player in this market with a large market share.

Wagner has and will be a German firm with modern technology producing

products with high quality. We are a company that is innovative and we have

an extensive product range catering to both the wet as well as powder

coating industry”.

Talking to IPC about the launch program, Mr. Imtiaz appreciated the

significant role of our website India

Powder Coating in the powder coating industry and mentioned that the

virtual media is now much faster and has strong penetration compared to any

other media.

About Wagner

WAGNER is a market-leading manufacturer of high tech products and systems

for coating and decorating with paints and powder. Their customers are

manufacturers, contractors as well as consumers.

The products of Wagner are user friendly and reliable. Combined with their

worldwide service network Wagner is a distinctive supplier in the surface

finishing market. In order to ensure high levels of customer satisfaction,

they are strongly committed to innovative, high technology engineering, and

quality manufacturing.

The WAGNER-Group employs approx. 1800 people worldwide and in the 2007

business year, the total turnover was approx. € 400 million. Over the 50

years since it was founded the WAGNER Company has, from modest beginnings,

become a global company with 9 production plants, 11 international sales

companies and about 50 international WAGNER agencies. WAGNER is organised in

two divisions:

The division Decorative Finishing provides paint application and

redecorating equipment plus solar lamps for the Do-It-Yourself market as

well as equipment for the machine application of paints, lacquers and

plaster in the painting contractor business.

The division Industrial Solutions is a specialized worldwide provider of

systems and components in industrial surface technology, offering high

technology, high quality equipment and systems for the application of powder

and liquid media.

Dow Chem to turn Pune unit into R&D hub

Chemicals and polymers manufacturer Dow Chemicals plans to develop its Pune

unit into a global research and development centre that will focus on a wide

spectrum of products which give it an edge in the Indian and international

market.

The $54 billion giant believes that the wide talent base available in India

and the network of Indian research institutions in the field of chemistry

will help make the Centre of Excellence for chemistry research in Pune on

par with its centres in the Unites States and a couple more proposed to be

set up in Shanghai and Europe.

Ramesh Ramachandran, president and chief executive officer, Dow Chemicals

International, said today that the centre, the first of its kind outside the

US, will focus on discovering new molecules and develop novel applications

for existing ones. <more>

Cash-rich ICI may paint buyout plan

KOLKATA: ICI India, now a part of the Akzo Nobel Group, is likely to weigh

acquisitions post merger and after it decides on selling its natural starch

division.

ICI India would have an overall cash kitty of Rs1,000 crore along with

additional funds that it could raise for the purpose of acquisitions.

Dutch chemical major Akzo Nobel had acquired ICI Plc in the beginning of the

New Year for $16.2 billion and a change in the name of ICI India and board

composition is expected to come through in the next two quarters. ICI India

is a subsidiary of ICI Plc.

M R Rajaram, director, ICI India told DNA Money, “ICI is always looking for

value-enhancing opportunities and the same effort will continue in the

future also. Post merger, it will be a cash rich company and opportunities

for acquisition will be stronger.”

Exodus from Nashik goes up to 20,000

NASHIK: About 20,000 north Indians have left Nashik after the MNS agitation.

The worst affected has been the industry as most contract labourers here are

north Indians ready to work for at least Rs90-100 less. After the violence,

15% of the industries, all of them small-scale units, have been shut and

about 40% affected badly.

“We never expected such a problem of human resource. We have tackled

infrastructural, power, water, material and octroi problems, but this is

very different,” says Dhananjay Bele, president, Ambad Industries and

Manufacturers' Association.

The exodus has left companies fighting for manpower<more>

Painting a rosy picture of manufacturing

NEW DELHI: The latest quick estimates suggest considerable slowdown in the

index of industrial production, but it seems sooner rather than later that

proactive fiscal policy — read lower excise duty — and supportive monetary

policy — lower policy interest rates—would boost demand for manufactures

right across the board.

One key indication of turnaround industrial growth is the buoyant demand for

industrial paints. The figures suggest that from 33% revenue-share in the

overall market for coatings, industrial paints would soon account for 50% of

the total in India. <more>

Paints get a fresh coat as realty peaks

The paints industry has been quick to capitalise on the current phase of

economic growth. Factors like growing real estate development and higher

disposable income, which is driving premium paint consumption, are

contributing to an increase in decorative paint sales. And a rising number

of industrial and infrastructure projects are driving demand for industrial

paints.

The only negative factor is the slowdown in the automobile sector that has

affected automotive paint sales. In the December 2007 results, major paint

companies have shown robust growth in both sales and profits. Part of it is

due to a late Diwali, pushing dispatches into the third quarter. <more>

Powder Coating Educational Tour

Set for 2008

The International Surface Finishing Academy (ISFA) has announced the dates

and locations of its Powder Coating Courses for 2008. The courses,

instructed by the powder coating experts of TIGER Drylac USA, cover the

fundamentals of powder coating from both commercial and industrial

perspectives.

The locations and dates for the 2008 courses are as follows:

Miami, Fla., Feb. 19-20

Denver, Colo., April 9-10

Chicago, Ill. June 3-4

Mystic, Conn., Aug. 5-6

Charleston, S.C., Sept. 15-16

San Diego, Calif., Nov. 5-6

Over a period of two days, students will be instructed in a wide variety of

relevant topics, including pretreatment, shop and equipment maintenance,

equipment selection, oven and cure issues, powder selection,

troubleshooting, and tips and tricks for the custom coater. Participants

will be fully instructed in the formulation and manufacture of powder

coating.

OSHA Issues Enforcement

Procedures Directive for Hex-Chrome Standards

The Occupational Safety and Health Administration (OSHA) has issued a new

compliance directive for occupational exposure to hexavalent chromium [Cr(VI)].

The directive, OSHA Instruction CPL 02-02-074, Inspection Procedures for the

Chromium (VI) Standards, became effective Jan. 24, 2008.

"This new directive provides guidance for enforcement of the final rule on

hexavalent chromium standards," said Edwin G. Foulke, Jr., OSHA’s Assistant

Secretary of Labor. "OSHA anticipates these efforts will reduce the risks of

exposure to Cr(VI), thereby improving the safety and health of employees

affected by this hazard." <more>

Berger Paints` board approves to hike authorized capital

Berger Paints India announced that the board of directors of the company at

its meeting held on Feb. 26, 2008 and subject to the approval of the

shareholders by postal ballot and such other approvals as may be required,

has decided to increase the authorized capital of the company from Rs

650,000,000 to Rs 750,000,000 divided into 375,000,000 ordinary (equity)

shares of Rs 2 each.

The board has also approved to issue up to 20,000,000 warrants on a

preferential basis to the promoters or promoter group of the company with a

right exercisable by the warrant holder(s) to subscribe to the equity share

of the company on the basis of one fully paid equity share for one warrant.

The company has further informed that the proceeds of the aforesaid issue

will be utilized for financing normal capital expenditures of the company

including new projects, modernization and expansion proposals. <more>

Lyon Antimicrobial Lockers

Lyon Antimicrobial Lockers inhibit bacterial, mold, and odor build-up on

locker surfaces, as well as the touch transfer of microbes on locker handles

and doors. The lockers are finished in an advanced powder-coating

technology

from DuPont and Agion Antimicrobial. The coating includes a compound that is

completely inorganic, less toxic than ordinary table salt, and less

irritating than talcum powder. The compound has been approved for medical

devices and food contact applications.

Here's how it works: Any moisture on the locker triggers the controlled

release of powerful silver ions. These silver ions are noxious even to the

drug-resistant MRSA superbug and provide superior antimicrobial protection

for decades.<more>

Nanotechnology-based Conversion Coating - Henkel Technologies

Bonderite NT is a

nanotechnology-based conversion coating for metals and is said to be free of

phosphate and toxic heavy metals, to be ultra thin, uniform and make

production process economical. This coating is suitable for surface

pretreatment for conventional powder and wet paint coatings. It can be

applied by dipping or spraying and creates a cohesive, inorganic,

high-density layer incorporating nanoparticles. The process has low energy

needs (saving money) and is also distinguished by its entire lack of organic

ingredients.

PPG Industries-Nanotechnology

PPG Industries has acquired the assets and intellectual property of

NanoProducts Corporation, a producer of nanoproduct materials and a

developer of nanoproduct technology. Terms were not disclosed.

The nanoparticle technology company has an extensive patent estate and

operates pilot facilities for the development and manufacture of unique

nanoparticles.

“This acquisition significantly strengthens PPG’s nanotechnology patent

portfolio and positions us as a world leader in nanoengineered materials,”

said James A. Trainham, PPG’s vice president of science and technology. PPG

will also license nanotechnology solutions, particularly in areas outside

its existing businesses. (Source: PPG)

109 jobs to go at Akzo Nobel

ONE of East Lancashire's biggest employers has been accused of a betrayal

after axing 109 jobs.

Akzo Nobel, which has 650 staff at Crown House, Hollins Road, Darwen, will

move manufacturing of its industrial paints to Sweden at the end of the

year.

Last November bosses pledged there would be no job losses after the

Competition Commission ruled that the Dutch firm had to sell its Crown Paint

division following a takeover of rival chemical firm ICI.

Speaking at the time managing director of Akzo Nobel UK Howard Luft told the

Lancashire Telegraph the business was a "big success story".

He said: "There will not be job losses. This company is being sold as a

strong competing business. 2007 has been a great year for us."

Mr Luft was unavailable for comment today, but John Bowland, managing

director for the industrial finishes department, said job losses were due to

the "economic performance" of the site.<more>

Sherwin-Williams

Sherwin-Williams has signed an agreement to acquire the liquid coatings

subsidiaries of Inchem Holdings, Asia’s leading coatings supplier to

furniture and electronics manufacturers.

Headquartered in Singapore, Inchem produces coatings applied to wood and

plastic products in Asia. These waterborne, solvent-based and ultraviolet

curable coatings are applied to furniture, cabinets, flooring and electronic

products that are manufactured both for export as well as domestic sale. The

coatings are made and sold in China, Vietnam and Malaysia and distributed to

15 other countries throughout Asia.

Inchem has more than 400 employees across its four manufacturing plants and

sales of approximately US$ 30 million.

Christopher M. Connor, Chairman and CEO of the Sherwin-Williams Company,

said “this acquisition reaffirms our commitment to growing globally through

organic growth accelerated by strategically important acquisitions.”

Sherwin-Williams Acquires Becker Powder Coatings

The Sherwin-Williams Co. has acquired Becker Powder Coatings Inc. in North

America, a subsidiary of AB Wilh. Becker based in Sweden. Simultaneously, AB

Wilh. Becker has acquired the North American coil coatings business of

Sherwin-Williams and related assets.

PPG's cost-cutting

to close plants in Europe

Friday, February 22, 2008

PPG Industries Inc., the world's second-biggest paint maker, plans to close

some European factories acquired with the purchase of SigmaKalon Group BV to

meet cost-saving targets.

The paint plants, which haven't been identified, will be shut by 2010 to

help attain savings equal to 3 percent to 5 percent of SigmaKalon's sales,

Jack Maurer, a spokesman for Pittsburgh-based PPG, said Thursday. Savings

also will come from bulk raw-material purchases and cutting administrative

expenses in Europe, he said.

PPG, led by Chief Executive Officer Charles Bunch, bought SigmaKalon for

$3.25 billion on Jan. 2 from Bain Capital LLC to double sales of coatings,

its largest business, in Europe. The company hasn't developed a specific

plan for closing plants, Maurer said. <more>

Damage significant

from Akzo-Nobel fire

Wednesday, February 20, 2008 12:22 PM CST

A fire at Akzo-Nobel Saturday night caused an estimated $100,000 damage,

according to the Morris Fire Department.

Morris firefighters responded at 7:20 p.m. and reported the fire was in a

fiberglass thermal oxidizer vessel. A thermal oxidizer is a pollution

control device.

Fire Chief Robert Coleman said the 100-foot tower was down for maintenance.

Apparently when oxygen hit some residue in the vessel it ignited. <more>

|