|

||

|

||

|

|

||

|

||

|

||

|

||

|

||

|

|

|

|

||

|

|

|||||||||||||||

|

|

|

|

||||||||||||||

|

|

|||||||||||||||

| Green News |

| Green Living

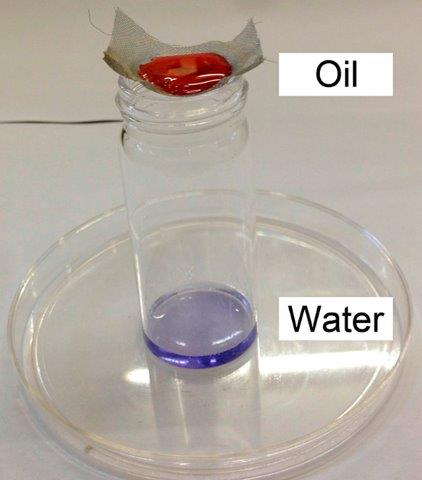

Tips A page dedicated to the Green News and tips is now added. It has articles with tips for going green to help protect the environment we all affect. Earth friendly advice for going green, reducing costs, consumption & impact on the environment! These widgets! displays the title and a snippet from recent articles published on GLT and the other, headlines from http://www.greenlivingtips.com New smart coating could make oil-spill cleanup faster and more efficient "Ultrafast Oleophobic-Hydrophilic Switching Surfaces for Antifogging, Self-Cleaning, and Oil-Water Separation" ACS Applied Materials & Interfaces  In

the wake of recent off-shore oil spills, and with the growing popularity of

“fracking” — in which water is used to release oil and gas from shale —

there’s a need for easy, quick ways to separate oil and water. Now,

scientists have developed coatings that can do just that. Their report on

the materials, which also could stop surfaces from getting foggy and dirty,

appears in ACS Applied Materials & Interfaces. In

the wake of recent off-shore oil spills, and with the growing popularity of

“fracking” — in which water is used to release oil and gas from shale —

there’s a need for easy, quick ways to separate oil and water. Now,

scientists have developed coatings that can do just that. Their report on

the materials, which also could stop surfaces from getting foggy and dirty,

appears in ACS Applied Materials & Interfaces.J.P.S. Badyal and colleagues point out that oil-spill cleanup crews often use absorbents, like clays, straw and wool to sop up oil, but these materials aren’t very efficient because they also sop up a lot of water. Extra steps and equipment also are needed to remove the oil from the absorbent, which is difficult to do on a ship. Recently, researchers have turned their attention to new smart materials called “oleophobic-hydrophilic” coatings that instead let the water through and repel the oil. However, the films that have been reported so far take several minutes to do the separation, are complicated to make or aren’t very good at repelling oil. So, Badyal’s team set out to improve these materials.<more> Allied Powder Coating cited for 15 safety and health violations by OSHA HOUSTON – Outdoor Furniture Refinishing Inc., doing business as Allied Powder Coating, has been cited by the U.S. Department of Labor’s Occupational Safety and Health Administration for 15 serious health and safety violations with a proposed fine of $55,440. OSHA cited the sandblasting and powder coating company for exposing workers to toxic chemicals, including silica, beyond established occupational limits. OSHA initiated the February 2013 inspection at the company’s Houston facility under its Regional Emphasis Program on Safety and Health Hazards in the Manufacture of Fabricated Metal Products.<more> |

| Infomercials | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Note: The infomercials are in alphabetical order. No other priorities associated.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| News |

|

Asian Paints closes Bhandup plant in Mumbai Asian Paints today said it has closed down its oldest plant at Bhandup in Mumbai and all employees of the unit have either taken voluntary retirement or shifted to its some other plants. The Bhandup plant had started production in 1958 and had employee strength of over 100. "The company has discontinued manufacturing activities at the plant with effect from May 5, 2014," Asian Paints said in a filing to the BSE. It further said that the company had offered a voluntary retirement/separation scheme along with an alternate option of relocation to its other factories/establishments to all workmen of the Bhandup plant. "All workmen have accepted either the Voluntary Retirement/Separation Scheme or relocation to another factory/establishment of the company," it added. The Bhandup plant had an installed capacity of 30,000 kl per annum. It was producing decorative paints.<more> Kansai Nerolac Q4 net down 63 per cent at Rs 45 crore Nerolac had reported net profit of Rs 122.7 crore in the January-March quarter of 2012-13 fiscal mainly on account of exceptional income of Rs 114 crore. NEW DELHI: Kansai Nerolac PaintsBSE 0.05 % on Wednesday reported 63.4 per cent decline in standalone net profit at Rs 44.9 crore for the fourth quarter ended March 31, 2013-14. The company had reported net profit of Rs 122.7 crore in the January-March quarter of 2012-13 fiscal mainly on account of exceptional income of Rs 114 crore. Net sales during Q4, 2013-14 were at Rs 743.7 crore, an increase of 10.06 per cent as compared to Rs 675.7 crore in the year-ago period, the company said in a BSE filing. Overall expenses during Q4 stood at Rs 681.8 crore, up 9.71 per cent as against Rs 621.4 crore in the same quarter last year. <more> Jenson & Nicholson (India) reports net loss of Rs 3.02 crore in the March 2014 quarter Sales decline 10.85% to Rs 13.56 crore Net Loss of Jenson & Nicholson (India) reported to Rs 3.02 crore in the quarter ended March 2014 as against net loss of Rs 3.22 crore during the previous quarter ended March 2013. Sales declined 10.85% to Rs 13.56 crore in the quarter ended March 2014 as against Rs 15.21 crore during the previous quarter ended March 2013. For the full year,net profit reported to Rs 35.31 crore in the year ended March 2014 as against net loss of Rs 5.84 crore during the previous year ended March 2013. Sales declined 9.66% to Rs 53.41 crore in the year ended March 2014 as against Rs 59.12 crore during the previous year ended March 2013.<more> Berger Paints hikes decorative paint prices by 1% The paint maker took the price hike to cover raw material cost increase, says Abhijit Roy, MD, Berger Paints. Kolkata-based Berger Paints has hiked decorative paint prices by a percent. The paint maker took the price hike to cover raw material cost increase, says Abhijit Roy, MD, Berger Paints. He says international monomer prices increased due to supplier plant shutdown. Monomers is used in emulsions for water-based paints. “We do not see major demand pullback due to price hike,” he told CNBC-TV18. Going forward, Berger expects double-digit growth trend to continue led by decorative segment. This is basically because of increases in the price of monomer which are used for emulsions. Off late, the monomer prices have been going up worldwide, possibly on account of two shutdowns that have happened; especially the one in Japan. Due to this reason, the monomer prices have shot up by a bit and to cover this raw material price increase, we have taken a slight increase. But, we have also said that it has stabilised and I don’t think we will need to make further increases in price, immediately. <more> Berger Paints Q4 net up 26% at Rs 55.34 crore Company had posted consolidated net profit of Rs 43.8 crore during the January-March quarter of last fiscal Berger Paints today reported 26.34% increase in consolidated net profit at Rs 55.34 crore for the fourth quarter ended March 31, 2014. The company had posted consolidated net profit of Rs 43.8 crore during the January-March quarter of last fiscal, 2012-13, Berger Paints said in a filing to the BSE. The company's net sales during Q4, 2013-14 stood at Rs 963.49 crore, an increase of 19.57% as compared to Rs 805.78 crore in the year-ago period. Overall expenses in Q4 stood at Rs 880.79 crore, up 19.60% as compared to Rs 736.4 crore in the corresponding period last year. During FY'14, the company's net profit stood at Rs 249.39 crore, against Rs 218.4 crore in previous financial year. Net sales in 2013-14 were at Rs 3,854.46 crore as compared with Rs 3,334.6 crore in the same period last year.<more> BASF India drops after weak Q4 results BASF India lost 3.48% to Rs 756.80 at 13:15 IST on BSE after net profit dropped 50.8% to Rs 6.56 crore on 30.3% growth in net sales to Rs 1067.32 crore in Q4 March 2014 over Q4 March 2013. The company announced the results after trading hours on Tuesday, 29 April 2014. Meanwhile, the BSE Sensex was up 55.86 points or 0.23% to 22,518.81 On BSE, so far 3,193 shares were traded in the counter as against average daily volume of 9,646 shares in the past one quarter. The stock hit a high of Rs 764 and a low of Rs 751.40 so far during the day. The stock had hit a 52-week low of Rs 490 on 7 August 2013. The stock had hit a record high of Rs 867.40 on 31 March 2014. The stock had underperformed the market over the past one month till 29 April 2014, falling 8.42% compared with the Sensex's 0.56% rise. The scrip, however, outperformed the market in past one quarter, advancing 31.33% as against Sensex's 8.81% rise. The company has an equity capital of Rs 43.29 crore. Face value per share is Rs 10.<more> Akzo Nobel Q4 Net Down 12.6 Per Cent at Rs. 54 Crore Paints and coatings maker Akzo Nobel India on Friday reported a 12.64 per cent decline in net profit at Rs. 54.6 crore for the fourth quarter that ended on March 31, due to a fall in other income. The company had posted a net profit of Rs. 62.5 crore for the corresponding period a year ago, it said in a filing to the BSE. During the quarter under review, net sales stood at Rs. 601.2 crore, up 14.60 per cent from Rs. 524.6 crore a year ago. Other income during the quarter stood at Rs. 22.5 crore as against Rs. 51.1 crore in the corresponding quarter last year. CCP Directs Paint company to remove claim 'No 1 in Pakistan' from its marketing campaign ISLAMABAD, 23 MAY 2014: The Competition Commission of Pakistan (CCP) while conducting a hearing in a show cause notice issued for prima facie violation of Section 10 of the Competition Act, 2010 directed M/s Jotun Pakistan (Pvt) Limited to withdraw all marketing material from the public domain containing the claim ‘No. 1 paint in Pakistan’ within two weeks. The matter was heard by a three member bench of CCP comprising of Dr. Joseph Wilson, Chairman, Mr. Mueen Batlay and Dr. Shehzad Ansar, Members. CCP has also directed that an undertaking/comprehensive compliance report on behalf of Jotun Pakistan be filed with CCP in this regard. CCP has required Jotun Pakistan to issue directions to all of its retailers, vendors, distributors and dealers not to use the aforesaid claim in any marketing or promotional material. The Chief Executive Officer of Jotun Pakistan, Per Arne Langnes, has assured CCP for issuance of the comprehensive compliance report within the stipulated time. The proceedings were initiated on complaints filed by M/s. Diamond Paints Industries (Pvt) Limited and M/s. Akzo Nobel Pakistan Ltd under Section 10 of the Competition Act, 2010. <more> Powder Coatings Market - Europe and North America were the other key markets for powder coatings The global market for powder coating is expected to reach USD 12.48 billion by 2020, according to a new study by Grand View Research, Inc. Growing support for the use of powder coatings in comparison to conventional liquid paints by regulatory agencies such as EPA and REACH on account of negligible VOC emissions is expected to be a key driver for market growth. In addition, growing application demand with regards to automotive, appliances and consumer goods is also expected to drive powder coating sales over the next six years. Consumer goods are the largest application market for powder coatings, with estimated consumption of 437.3 kilo tons in 2013. Automotive and general Industries were the key application markets, with combined powder coating sales expected to reach USD 5.11 billion by 2020. Powder coating demand in furniture was relatively small in 2013 but is expected to witness substantial growth of over 7.6% from 2014 to 2020. Nippon Paint to invest P100-M in PH  MANILA, Philippines – Nippon Paint will be investing P100 million into its Philippine arm, Nippon Paint (Coatings) Philippines, to rake in more sales in the next three years. Nippon Paint Malaysia Group, the owner of Nippon Paint (Coatings) Philippines, is targeting P1.5 billion in sales turnover by 2017. As part of its expansion strategy in the country, Nippon Paint (Coatings) Philippines will deploy its Nippon Colour Creations tinting machines to be housed in paint centers and modern trade outlets nationwide. “Worrying of being told that their preferred color is not available or in stock is now a thing of the past with Nippon Paint Colour Creations tinting machines. In fact, with over 10,000 paint formulations in our library, Filipinos will soon be spoilt for choice,” said Nippon Paint Malaysia Group managing director Yaw Seng Heng.<more> Akzo Nobel invests 140 mln euros in new German plant * Opens new highly energy efficient membrane electrolysis plant in industrial heart of Germany * Capacity has been increased by 50 percent whilst at same time reducing plant's overall ecological footprint by some 20 percent * Plant involving a eur140 million investment by company * Commercial production from new plant expected to come on stream in next few weeks PPG SUPPLIES METAL COATINGS TO ONE WORLD TRADE CENTER DURANAR coatings featured on 11-story podium  PITTSBURGH, May 1, 2014 – PPG Industries’ (NYSE:PPG) building products group announced that DURANAR® coatings are being used to paint the 11-story podium portion of One World Trade Center, the 104-story skyscraper that will soon open as the centerpiece of the new World Trade Center complex in New York. Two colors of Duranar coatings – Bright Silver and Ozark Shadows – were specified for the project. They will be used to paint an aluminum screen that will be fronted by a pattern of glass fins protruding from slatted stainless steel panels. The aluminum screen will be illuminated by energy-efficient LED lights, visible through the slats, which will make the podium sparkle at night. Scott Moffatt, PPG market manager, building products, said PPG is pleased to have its coatings featured on such an iconic structure. “One World Trade Center will be recognized around the world as a symbol of America’s strength and resilience,” he said. “To have our products appear prominently on such a visible part of the building is an honor for PPG and its project partners.” The podium, which is designed to protect the lobbies and lower-level mechanicals of One World Trade Center, will feature nearly 700,000 pounds of aluminum extruded and painted by Keymark Corp., Fonda, N.Y., a member of the PPG CAP CERTIFIED APPLICATOR PROGRAM group. Duranar coatings will cover 169,000 square feet of the building’s surface area.<more> There’s Metal In Your Dairy Products  How

about a side of silver with your yogurt? According to a report by the

Project on Emerging Nanotechnologies (PEN), your yogurt—along with 96 other

food items, most of which are found in the dairy aisle—contains nano-sized

particles of titanium dioxide. And that number is up from just eight foods

in 2008. How

about a side of silver with your yogurt? According to a report by the

Project on Emerging Nanotechnologies (PEN), your yogurt—along with 96 other

food items, most of which are found in the dairy aisle—contains nano-sized

particles of titanium dioxide. And that number is up from just eight foods

in 2008.A particle qualifies as "nano" when it's 100 nanometers wide or less (to put it into context, a strand of hair is about 80,000 nanometers in diameter). Nanotechnology is used in everything from toothpaste to tennis balls to socks (when broken down, silver has antimicrobial properties), and PEN finds there are more than 1600 nanotechnology-based consumer products on the market today. But when it comes to your food, nano-sized titanium dioxide is used as a color-enhancer to ensure dairy products like yogurt and soy milk are their traditional bright white.<more> Axalta Coating Systems opens new commercial offices in Spain Axalta Coating Systems, a leading global supplier of liquid and powder coatings, has opened new commercial offices for its Spanish operations in Sant Cugat del Vallès near Barcelona, Spain. The 550m2 facility is home to Axalta’s powder, liquid industrial, OEM and refinish businesses. It is designed to welcome visitors with a dedicated showroom to display the company’s powder coating family of brands, four spacious meeting rooms and a reception area.<more> India Imports of TiO2 hiked up by 11% in March 2014 as compared to last month imports. |

| Ask Joe Powder |

"Ask

Joe Powder" "Ask

Joe Powder""Ask Joe Powder" is a question and answer column authored by Kevin Biller of the Powder Coating Research Group. Mr. Biller has over 30 years experience formulating and manufacturing powder coatings. He welcomes your questions regarding powder coating technology. Please write to: askjoepowder@yahoo.comor post your question through the your facebook idhttp://letsfinishit.com/askjoe.htm Kevin Biller The Powder Coating Research Group 15 W. Cherry Street, 3rd Floor Columbus, OH 43215 614-354-1198 www.powdercoatingresearch.com Dear Joe, I hope that you and your family are well. Long time no see. How is your business? I have a question, regarding Qualicoat Class 1 approval. For polyester-TGIC powder coating the gloss should not be less than 50% after 1000 hours Xenon Arc exposure.I want to know if a powder based on a standard polyester-TGIC resin will pass this test (approximately equivalent to 1year Florida). Or do we need another type of polyester resin for class1 or no? My pleasure will be hearing from you. Regards, SEDDIGHIAN Hello Seddighian, All is well here. We celebrated our oldest daughter's birthday today. It was a wonderful day. I hope you and your family are well. And my business is doing well – we continue to grow each year. A standard grade TGIC-polyester will meet the Qualicoat Class 1 specification. It is important to confirm mortar and sulfuric acid resistance performance and to select your polyester resin from a reputable resin supplier. In addition it is wise to make sure that the pigments and additives are weather resistant. Some waxes are not UV durable. In addition many organic pigments will fade from one year Florida exposure. So choose you additives and pigments wisely. I hope that this helps. Kind regards, Joe Dear Joe, What is the best way to measure weatherability and cheapest way?QUV,Xenon Arc or Solarbox?I want to get machine for my laboratory.What is your suggestion? Best regards, Ozlem HelloOzlem, The very best way to ascertain resistance to outdoor conditions is natural exposure (this is expensive and takes years). Second best weathering simulation technique is exposure to concentrated sunlight through the use of solar reflectors and water mist and is commonly known as EMMAQUA or equatorial mount with mirrors for acceleration and water (ASTM D4141). This technique utilizes real solar energy but because the energy is concentrated by mirrors the duration is significantly reduced. ASTM D4141 testing requires the careful measurement of UV light exposed to. The amount measured is then compared to historical data of Florida exposure and correlated to the number of months of typical exposure. This is also very expensive. Next best technique is Xenon Arc Weatherometer (ASTM D-6695). For artificial tests the wavelengths of xenon arc emission best simulate sunlight. These cabinets are relatively expensive to buy and costly to operate. Click here for answer with pictures and graphs Next in relevance is QUV (ASTM D-4587). This is tried and true, but not as representative of sunlight as the tests described above. I would use 340-A lamps as the shorter wavelengths (B-313) are selectively too damaging to polyester resin backbones. QUV cabinets are much less expensive than Xenon Arc units. I bought a used one for less than $2000. New ones cost around $10,000 to $12,000. You may want to consider building a rack and exposing test panels at your own facility as well. Hope this helps. Kevin |

| Events / Seminars / Exhibitions | ||||||||||||||||||||||||||||||

| On this Coating

Calendar you will find a wide variety of industrial events in the field of

coatings, adhesives, sealants, construction chemicals and coatings

application. Please click here to view the complete Coating Calendar

|

||||||||||||||||||||||||||||||

| Documents/ Books / Periodicals/ Brochures / Videos |

| TROUBLE SHOOTING By Niraj Rajput Area Sales Manager-Industrial Sales Pune at Kansai Nerolac Paints Ltd Normal problems which can arise in connection with powder coating with their suggestions for solution are given below: 1. Problem/Fault: Coat too thin/impossible to increase thickness. Suggested action • Increase voltage, increase fluidization. Increase powder feed • Check resistance between different support/objects on conveyer, ideal film reading is 0 ohm. • Check earth connection from conveyer and outward. • Check spraying equipment fuses, voltage, electrodes in gun mouth, all electrical connections to high tension cable. • Check powder by using another powder spray gun. 2. Problem/Fault: Thin or no coat at support hooks. Suggested action • Problem is due to poor earth connection and should be investigated. • Also check earthing and powder level in feed hopper. 3. Problem/Fault: Poor flow /orange peel effect. Suggested action • Adjust spray gun equipment parameters for uniform powder out put, to get recommended film thickness. • Use fastest possible heating cycle in oven. • Check optimum distance between object and gun mouth. 4. Problem/Fault: Different powder outputs from guns. Suggested action • Different hose lengths between powders feed and gun. • Air pressure too low. • Ejector fault or partial blocking of ejector hose or gun. 5. Problem/Fault: Yellow or brown spots or stripes on the final coat. Suggested action • Poor cleaning. • Residues of cleaning agent. • Check that compressed air is free of water and oil. 6. Problem/Fault: Improper Curing. Suggested action If problems arise due to over or under curing from oven • Check that all thermostats are working properly. • Check air circulation. • Check metal temperature using temperature recorder. 7. Problem/Fault: No powder from gun. Suggested action • Check all fuses. • Check compressed air & fluidisation pressure. • Blow through pneumatic system with air gun. 8. Problem/Fault: Particles/dirt in powder coat film. Suggested action • Check that product is completely clean before coating. • Prevent dust from entering spray booth. • Sieve powder and examine if contamination, residue in sieve. 9. Problem/Fault: Craters full depth. Suggested action Indicate contamination of object prior to coating • Check whether water-based paint has been used nearby. • Check whether there is silicon in any materials/lubricants etc. Often used when welding. 10. Problem/Fault: Craters-fish eyes. Suggested action Usually indicate contamination of the powder, though may also indicate contamination of the object. • Check that compressed air is free of water and oil. • Check that powder is free of craters when using another spray gun or by melting powder on a plate. • Test the powder coat on other objects. 11. Problem/Fault: Poor Adhesion and Mechanical Test performance. Suggested action • Ensure cleaning / Pre-treatment is proper. • Check if Under curing is taking place. • Check if substrate thickness or type is changed. • Ensure powder film thickness is proper. |

| People / Visit / Feedback |

People J J Irani to step down from Kansai Nerolac Paints Ltd's Board Dr. J. J. Irani, Chairman of Kansai Nerolac Paints Ltd and an Independent Director on the Board, has informed the Company that he does not wish to offer himself for re-election as an Independent Director at the forthcoming Annual General Meeting of the Company to be held on June 20, 2014 in Mumbai, when he retires by rotation at the AGM. Visits It was nice meeting Atul Joshi from Berger Paints while on his visit to Indore. Atul visited India Powder Coating and discussed about his activities and the developments in the company. Berger has designed and positioned it's product in the Indian continent as a quality supplier of international standards. He is a regular reader of the IPC e newsletter . He also mentioned, "Berger's new plant at Pune is scheduled to be operational by July " |

India Powder Coating

Vivek Soley

3, Lalaram Nagar, Indore, 452001 MP India

Phone 91 731 2492291

Mobile +91 9826297112

emails: ipconweb@gmail.com

Alternative email viveksoley@hotmail.com indiapowdercoating@yahoo.com,

While we have used our best efforts in collecting and preparing the information

on this website and newsletter, we do not assume, any liability for any loss or

damage caused by errors or omissions, whether such errors or omissions resulted

from negligence, accident or other causes. The user may use their own discretion

while using the information.